I recall a frantic call from a purchasing director in Spain last summer. His production line had ground to a halt because the bottom ends he bought from a budget supplier were jamming his seaming machines 1. The steel thickness was inconsistent, varying wildly within a single batch. It was a disaster that cost him thousands of Euros in wasted fruit and overtime wages. This is exactly why the source of your raw material matters more than the pennies you might save on the invoice.

I have found that Baowu steel provides the superior metallurgical purity and precise temper control needed for premium tinplate bottom ends. Its consistent surface finish and uniform coating weight significantly reduce the risks of cracking, leakage, and corrosion, protecting your brand from costly quality failures.

In this industry, we often focus heavily on the price of the finished lid, but the real story begins at the steel mill. Let me explain why we choose Baowu as our primary partner and what that means for your canning operations.

Why does using Baowu steel ensure better consistency for my ends?

You know the feeling when a batch of lids runs smoothly, and then the next box causes your seamer to stutter? I have spent years helping clients troubleshoot these issues, and it almost always comes down to the base metal.

Baowu steel ensures consistency because they use advanced automated gauge controls that strictly maintain thickness tolerances across the entire coil. This precision eliminates the "waves" and thick spots that cause seaming defects, ensuring that every bottom end you feed into your machine fits perfectly, shift after shift.

Consistency in raw materials is the backbone of high-speed manufacturing. When you are running a canning line at 400 or 600 cans per minute, you do not have time to adjust your seaming rollers for every new pallet of lids. The steel needs to be identical, meter after meter, ton after ton.

The primary advantage of sourcing from a tier-one mill like Baowu (Baosteel) versus smaller, private mills lies in their equipment capability. Baowu utilizes state-of-the-art 5-stand double reduction cold rolling 2 mills. These machines are equipped with automatic gauge control 3 systems that adjust the roller pressure in milliseconds. This results in a steel sheet with a "flat shape" and minimal crown (the tendency for steel to be thicker in the middle than at the edges).

For a bottom end, thickness variation is a critical defect. If the steel is too thick, the chuck in your seamer cannot drive it down properly, leading to a "sharp seam" or a "cutover." If it is too thin, you get a "loose seam," which is an open door for bacteria.

At Huajiang, we maintain a massive inventory of 10,000 to 100,000 tons of this specific material. We do not buy spot-market "secondary" plates. We buy prime coils directly from the mill. This means that when we stamp a 307# bottom end for you, the physical properties—yield strength 4, elongation, and thickness—are uniform. This uniformity allows your seamers to run at optimal speeds without frequent stoppages for adjustments.

Comparison of Steel Tolerances

To illustrate why this matters, I have compiled a comparison based on technical datasheets and our own incoming quality inspections.

| Feature | Baowu (Prime Quality) | Small Private Mill (Standard) | Impact on Can Making |

|---|---|---|---|

| Thickness Tolerance | ± 0.003 mm | ± 0.015 mm | Baowu steel prevents seamer jams caused by gauge variation. |

| Temper Consistency | Uniform across width | Harder edges, softer center | Uniform temper prevents "earing" and uneven flanges. |

| Surface Profile | Controlled Roughness (Ra) | Variable Roughness | Consistent roughness ensures the lacquer bonds correctly to the metal. |

| Edge Wave | < 2 mm (Flat) | > 5 mm (Wavy) | Flat steel feeds smoothly; wavy steel causes misfeeds. |

When you use ends made from consistent steel, you are essentially buying time. You are buying the ability to predict your production output accurately. You are removing a major variable from your quality control equation.

How can I verify the raw material mill certificate for my order?

I have met many buyers who file away the Mill Test Certificate 5 (MTC) without ever really looking at it, treating it like a receipt rather than a safety document. But in today’s market, verifying your materials is the only way to ensure safety.

You can verify the Mill Test Certificate by cross-referencing the Coil ID and Heat Number on your package with the digital data provided by the mill. A valid Baowu MTC will list the specific chemical composition and mechanical properties, proving the material meets international food safety standards like FDA and EU regulations.

The MTC is the birth certificate of your steel. It tells you exactly where the iron ore came from, how it was melted, and how it was treated. However, "fake certificates" are a real problem in the global steel trade. Some traders will buy one coil of premium steel and ten coils of inferior steel, then photocopy the premium certificate for all of them.

To protect my customers, I insist on full transparency. When you receive a shipment of bottom ends from Huajiang, we can trace that specific lot back to the original mother coil from Baowu. Here is how we dig deeper into verification.

Reading the "DNA" of the Steel

A genuine MTC contains specific data points that determine the steel’s suitability for food packaging. You should look for the "Chemical Analysis" section.

- Carbon (C): Usually between 0.05% and 0.12%. This determines hardness.

- Sulfur (S): This is an impurity. In premium Baowu steel, this is kept extremely low (often < 0.02%). High sulfur content makes the steel brittle and prone to rusting.

- Tin Coating Weight: This will be listed as something like "2.8/2.8" or "5.6/5.6". This number represents the grams of tin per square meter.

The Traceability Loop

We utilize a digital ERP system that logs the "Heat Number" (the batch of molten steel) and the "Coil ID" as soon as the raw material enters our warehouse in Fujian.

- Inbound: The coil is scanned. The MTC data is digitized.

- Production: When we slit the coil into sheets for printing or stamping, the system generates a new "Batch ID" linked to the Coil ID.

- Outbound: Your box of ends has a label. That label works like a QR code for history.

If you ever suspect a quality issue, you can send me the code on the box. Within minutes, I can pull up the original Baowu certificate. I can tell you the day it was rolled, the exact tin coating thickness measured at the mill, and the results of the hardness test.

Key Data Points for Verification

Use this table as a checklist when reviewing any MTC from your suppliers.

| Data Point | What it Indicates | Warning Sign |

|---|---|---|

| Standard Reference | The rulebook used (e.g., GB/T 2520, ASTM A623). | Missing standard or "Commercial Quality" label. |

| Coil/Package No. | The unique ID of that specific roll. | Duplicate numbers on different shipments. |

| Temper Code | Hardness (e.g., T3, T4, DR8). | Code does not match your order spec (e.g., received T5 instead of T3). |

| Date of Production | Age of the steel. | Steel older than 6 months faces "aging" issues (stretcher strains). |

By understanding these certificates, you regain control. You are no longer just trusting a supplier’s word; you are verifying the science behind the product.

Does premium steel reduce the risk of cracking during seaming?

The most terrifying sound in a cannery is the "pop" of a flange cracking, or worse, the silence of a micro-crack that you don’t discover until the cans swell in the warehouse.

Premium steel significantly reduces cracking risks because it has fewer non-metallic inclusions, which are microscopic impurities that create weak points in the metal. The high-quality annealing process at Baowu gives the steel the perfect balance of ductility and strength, allowing it to bend 180 degrees during seaming without fracturing.

Let’s get technical about why metal cracks. When you double-seam a can, you are forcing the steel to undergo severe plastic deformation. You are curling it tightly around the body hook. If the steel structure is not perfect, it will fail.

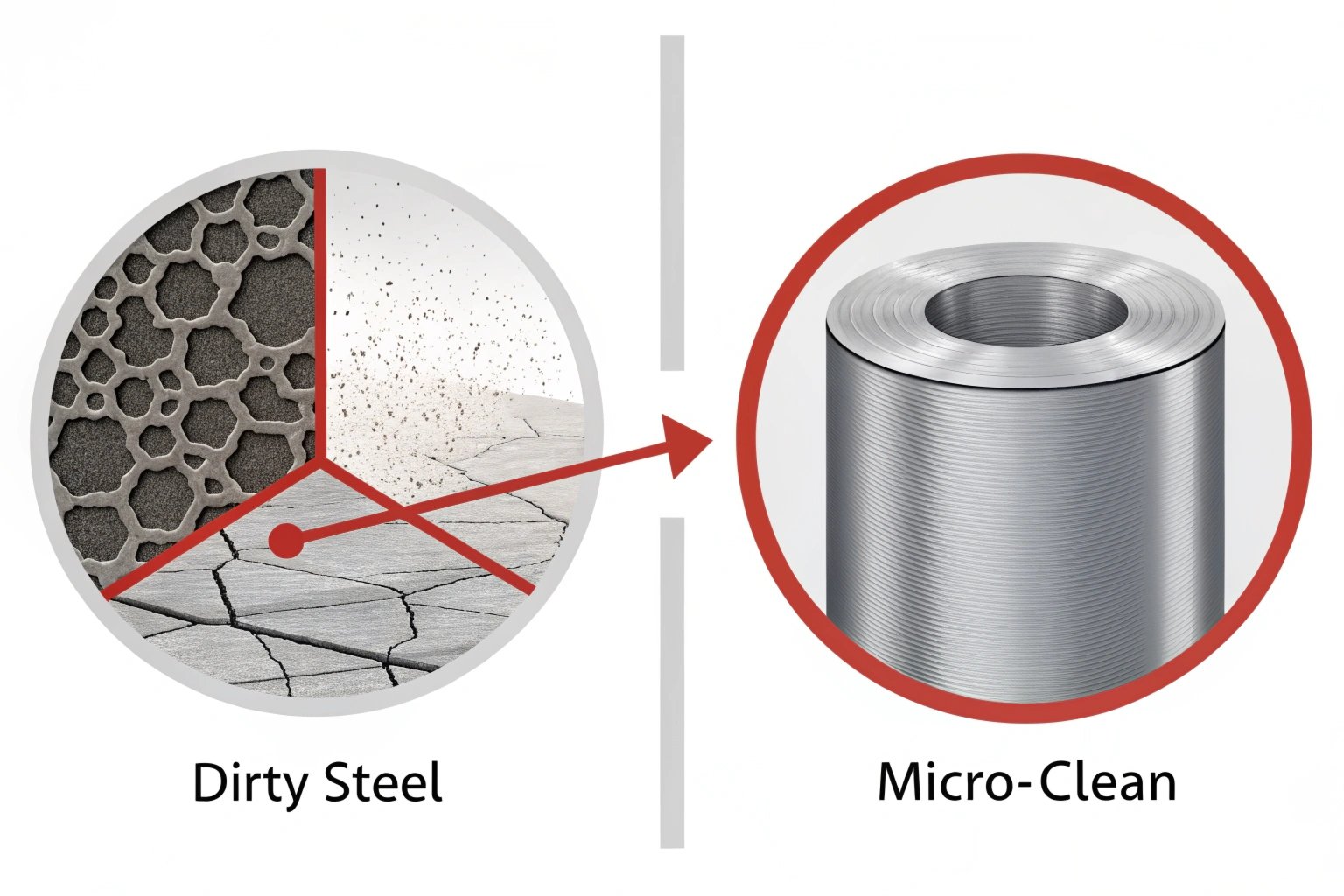

The main culprit for cracking is Non-Metallic Inclusions 6. Imagine trying to roll out pizza dough. If there are little hard pebbles in the dough, the dough will tear around those pebbles when you stretch it. In steel, these pebbles are microscopic bits of oxide or slag trapped during the melting process.

Baowu uses "Clean Steel" technology. They use vacuum degassing 7 and argon stirring in the ladle to float these impurities to the top, where they are removed. Small, budget mills often skip these expensive secondary refining steps. The result is "dirty" steel that looks fine but fails under stress.

The Role of Annealing

Another critical factor is the annealing method. There are two main types:

- Batch Annealing (BA): The coils are stacked in an oven for days. This is slower and can result in uneven heating—the outside of the coil is softer than the inside.

- Continuous Annealing (CA): The steel strip runs through a furnace at high speed. This is what Baowu uses for most premium grades.

Continuous Annealing 8 creates a uniform grain structure. It ensures that the "Yield Strength" and "Elongation" are consistent. For a bottom end, we usually use T3 or T4 temper (Continuous Annealing). This provides enough stiffness to hold the pressure of the food but enough flexibility to curl without cracking.

Anisotropy and Earing

Steel has a "grain direction" from rolling. When you stamp a round lid, the metal flows differently with the grain versus across the grain. If the steel quality is poor, this difference (Anisotropy 9) is large. This leads to "Earing"—wavy edges on the flange.

When the flange is wavy, the seaming rollers apply uneven pressure. High spots get crushed; low spots get missed. Both lead to leaks. Baowu’s control over the rolling texture minimizes this anisotropy, giving you a perfectly round, flat flange every time.

Defect Risk Assessment

Here is a breakdown of the risks associated with steel quality during the seaming process.

| Defect Type | Premium Steel (Clean & CA) | Budget Steel (Dirty or Mixed) | Consequence |

|---|---|---|---|

| Flange Cracking | Extremely Low | Moderate to High | Leakage, bacterial contamination (Botulism risk). |

| Skidding | Rare | Occasional | The chuck slips, damaging the coating and risking rust. |

| Wrinkling | Minimal | Frequent | The seam is not tight; "False Seam" potential. |

| Score Line Failure | Consistent | Variable | If making Easy Open Ends, the tab might rip off without opening. |

Using premium substrate is the best insurance policy against these defects. It ensures that the metal works with your machine, not against it.

Is there a significant price difference between Baowu and smaller mills?

I am a businessman, so I understand the pressure to cut costs. Every fraction of a cent counts when you are buying millions of units. But I also know the difference between "price" and "cost."

While Baowu steel typically carries a slightly higher upfront unit price than steel from smaller mills, it actually lowers your total production costs. The reduction in waste, the elimination of line stoppages, and the guarantee of zero quality claims make the premium option the most financially sound choice in the long run.

Let’s look at the numbers honestly. Yes, if you look purely at the price per metric ton of tinplate, Baowu might be 3% to 5% more expensive than a tier-2 or tier-3 mill in China. If you are buying a bottom end, that might translate to a difference of $0.0005 per piece.

On an invoice for 5 million ends, that looks like real money. But that calculation assumes a "perfect world" where every cheap end works perfectly. We do not live in a perfect world.

The Hidden Costs of "Cheap"

When you buy bottom ends made from inferior steel, you are importing risk into your factory.

- Downtime: If your seamer jams because of a thickness variation, how long does it take to clear? 15 minutes? One hour? If you are packing fresh tomatoes or fish, that downtime means raw material is rotting on the dock. The cost of the stoppage dwarfs the savings on the lids.

- Spoilage Rates: Standard allowable spoilage might be 0.1%. With inconsistent steel, I have seen spoilage rates spike to 1% or 2% during incubation. That is finished product—meat, sauce, labor, energy, and can—going into the trash.

- Tooling Wear: "Dirty" steel is abrasive. It wears down your seaming chucks and rollers faster. Premium steel is cleaner and often has better oiling/passivation, extending the life of your expensive tooling.

Our Economy of Scale

This is where Huajiang adds value. Because we are one of the largest purchasers of tinplate in the region (buying over 100,000 tons), we negotiate pricing with Baowu that a smaller factory could never get. We bridge the gap.

We buy the premium material at a bulk rate, process it efficiently on our 53 coating lines, and pass a product to you that is competitively priced against the "cheap" stuff, but with the quality DNA of a world-class mill.

Financial Comparison: Premium vs. Standard

Let’s analyze the Total Cost of Ownership 10 (TCO) for a standard canning run.

| Cost Component | Premium Steel (Huajiang/Baowu) | Cheap Steel (Market Standard) | The Reality |

|---|---|---|---|

| Base Material Cost | Baseline | -3% Lower | The only place the cheap option wins. |

| Line Efficiency | 99.8% Uptime | 95% Uptime | Lost production time kills profitability. |

| Seam Defects | < 1 in 100,000 | 1 in 1,000 | Sorting out defects requires extra labor. |

| Brand Reputation | Secure | At Risk | One recall costs more than 10 years of savings. |

In the end, the price difference is an illusion. The premium steel pays for itself by disappearing—it runs so smoothly you forget it’s there. You don’t have to manage it, worry about it, or fight with it. You just produce cans. That is the most profitable way to operate.

Conclusion

Choosing Baowu steel for your bottom ends is not just a purchasing decision; it is a strategic move to safeguard your production line. It transforms your raw material from a variable risk into a constant asset. Let’s discuss how we can integrate this stability into your supply chain for the next harvest season.

Footnotes

1. Overview of double seaming technology and machinery standards. ↩︎

2. Definition of the metalworking process for hardening steel. ↩︎

3. Technical explanation of thickness control systems in rolling mills. ↩︎

4. Material science definition regarding deformation under stress. ↩︎

5. Standard document certifying chemical and physical properties of steel. ↩︎

6. Detailed look at impurities that weaken steel structure. ↩︎

7. Method for removing impurities to create cleaner steel. ↩︎

8. Heat treatment process ensuring uniform metallurgical properties. ↩︎

9. Explanation of directional properties in materials causing earing. ↩︎

10. Framework for calculating direct and indirect product costs. ↩︎