Automation in Manufacturing Tinplate Bottom Ends

I know the specific headache you face when a shipment arrives. You open the container, and the first thing you worry about is not the price you paid, but whether these lids will jam your seaming machines 1. I have spent years on the factory floor, and I have seen how manual errors can destroy a production schedule. You need parts that fit perfectly, every single time.

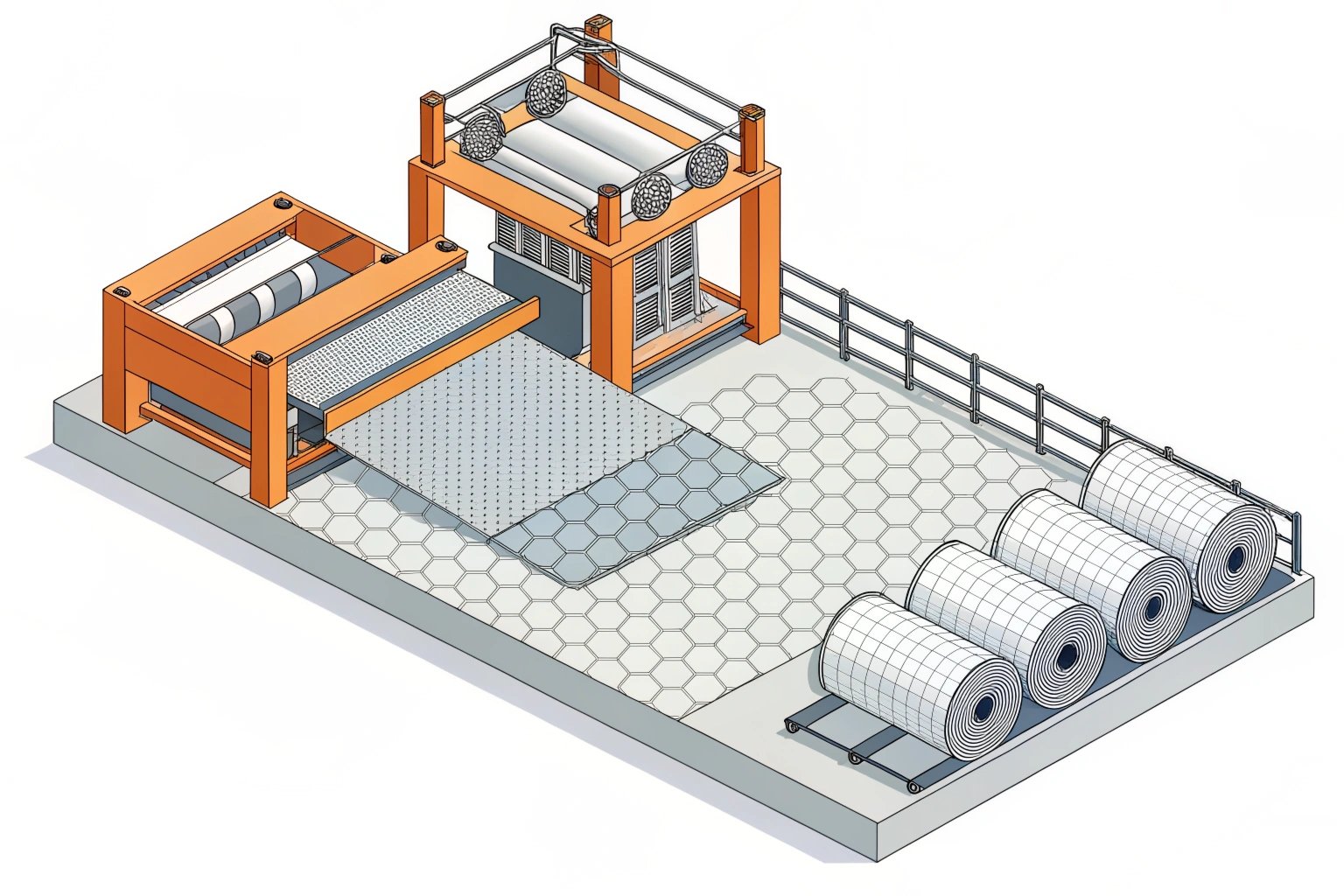

Automation in tinplate bottom end manufacturing integrates high-speed stamping, servo-controlled precision, and real-time visual inspection to eliminate human error. This technology ensures micron-level dimensional consistency, significantly lowers defect rates below 0.01%, and stabilizes unit costs by maximizing raw material utilization.

Let’s look at exactly how these machines change the game for your cannery and why shifting to a fully automated supplier is the safest move for your supply chain.

How does automation improve the dimensional consistency of my ends?

I remember the old days of manual adjustments on the press. A worker would get tired around 3 PM, the gauge would shift slightly, and suddenly, we had 5,000 lids that were just a fraction of a millimeter too wide. In your line of work, that tiny difference means a machine jam and hours of downtime. You cannot afford that risk.

Automated lines utilize servo-driven feeders and computerized pressure controls to maintain identical parameters for every single stroke. Unlike manual operation, these systems monitor metal flow and thickness in real-time, instantly adjusting to ensure every bottom end matches the precise specifications required for your seaming equipment.

When we talk about dimensional consistency, we are talking about the "Digital Twin" of your specifications. In a traditional, semi-manual factory, consistency relies on the skill of the operator. If the operator is having a bad day, your product suffers. In a fully automated setup, like the ones we operate at Huajiang, the machine follows a rigid digital recipe.

The Science of Servo Control

The key technology here is the servo motor system 2. Old machines used mechanical cams that would wear down over time, causing "drift" in the size of the lid. Servo motors do not drift. They use electrical signals to control the position of the metal sheet to within a fraction of a hair’s width. This means that the first Easy Open End (EOE) 3 produced on Monday morning is identical to the last one produced on Friday night.

Furthermore, automated lines address the issue of "fat cans" or loose seams by controlling the curl height and flange width. These are the critical areas where the lid meets your can body. If the curl is too tight, the seamer cannot grab it. If it is too loose, you get a leaker. Our automated systems measure these dimensions constantly. If the temperature in the factory changes and affects the metal expansion, the machine senses it and adjusts the pressure automatically. This removes the "guesswork" from manufacturing.

Impact on High-Speed Seamers

For clients like you who might run seamers at 600 or 800 cans per minute, a jam is a disaster. It stops the filler, the cooker, and the labeler. A manual factory might give you a tolerance of ±0.15mm. That sounds small, but at high speeds, it is a mountain. Automated lines tighten that tolerance to ±0.03mm. This consistency acts like a lubricant for your entire production line.

Here is a comparison of what you can expect regarding tolerances:

| Feature | Manual/Semi-Auto Tolerance | Fully Automated Tolerance | Impact on Your Production |

|---|---|---|---|

| Curl Height | ± 0.15 mm | ± 0.03 mm | Smoother seaming, fewer jams. |

| Countersink Depth | ± 0.20 mm | ± 0.05 mm | Better vacuum holding, less peaking. |

| Flange Width | ± 0.15 mm | ± 0.02 mm | Consistent overlap, secure seal. |

By removing the human variable from the physical forming process, we ensure that your high-speed filling lines can run at maximum capacity without stopping to clear jams caused by oversized or undersized ends.

Will automated lines significantly reduce the defect rate in my shipment?

Nothing ruins a business relationship faster than a leaking can on a supermarket shelf. I have lost sleep worrying about micro-leaks, and I know you have too. When a customer sends me a photo of a rusted or swollen can, it feels like a personal failure. Automation is my best defense against that feeling.

Yes, automated lines drastically reduce defect rates by removing the primary cause of variability: human handling. By integrating scroll shearing and automatic stacking, the system protects the sensitive coating from scratches and contamination, ensuring that the corrosion resistance of every end remains intact during production.

The biggest enemy of a tinplate bottom end is not the steel itself, but the damage done to the protective coating (lacquer) during the manufacturing process. In a manual factory, workers pick up stacks of metal sheets. They slide them onto the feeder. They pack the finished ends into bags by hand. Every time a human touches the product, there is a risk. A fingernail can scratch the lacquer. A drop of sweat can cause rust. A ring on a finger can dent the flange.

Eliminating the Human Touch

Automated lines solve this through "touchless" manufacturing. From the moment the coil of tinplate is loaded onto the decoiler until the finished ends are sleeved in paper, no human hand touches the metal. We use magnetic conveyors and air cushions to move the ends between the press and the lining machine. In older factories, ends were often dumped into a bin and then scooped up. This caused dents on the curl. Even a microscopic dent can prevent your seamer from creating a hermetic seal 4. By using automated magnetic rails, the ends travel in a single file, perfectly spaced, never banging against each other.

The Dust Problem Solved

Let’s dig deeper into the Scroll Shear 5 technology. In the past, cutting rectangular sheets created sharp edges and metal dust. This dust would float in the air and land on the wet coating inside the lids. Once cured, these dust particles created weak spots where acid from food (like your tomato paste or pineapples) could attack the metal. Modern automated scroll shears cut the metal in a zig-zag pattern inside a closed system with vacuum suction. This removes the dust before it becomes a problem.

We also have to talk about the compound lining. This is the rubber-like seal inside the lid. Manual machines rely on an operator to check if the nozzle is clogged. If they miss it, you might get 1,000 lids with missing compound. Our automated lines have sensors that detect the flow of the compound. If the flow drops even by 1%, the machine stops instantly. This guarantees that every single lid has the correct amount of sealant to protect your food product.

| Defect Type | Cause in Manual Process | Solution in Automated Process |

|---|---|---|

| Lacquer Scratches | Manual handling, sliding sheets. | Magnetic conveyors, air-cushion transfer. |

| Metal Dust Contamination | Open cutting, poor housekeeping. | Vacuum-assisted scroll shearing. |

| Missing Compound | Clogged nozzle, operator inattention. | Flow sensors, auto-stop function. |

| Dented Curls | Bulk bin collection. | Single-file magnetic transport. |

Does high automation translate to lower unit costs for my company?

You might look at my factory videos, see all the robots and computers, and think, "Chase, this looks expensive." It is natural to assume that high-tech gear increases the price of the product. But when I calculate my factory costs, the math shows me the exact opposite, and that benefits you.

High automation directly lowers unit costs by increasing speed to over 2,000 ends per minute and reducing material waste by up to 29% through smart nesting. Although the initial machinery investment is high, the massive reduction in labor costs and scrap generation results in a more competitive final price for you.

Let’s be honest about the cost of making metal packaging. The biggest cost is not the labor; it is the steel (tinplate) itself. Steel prices fluctuate, and waste is money thrown in the trash. This is where automation pays for itself.

Maximizing Raw Material Yield

We use a process called "Zig-Zag" or Scroll Shearing. Imagine you are cutting circles out of a square piece of paper. If you line them up in straight rows, you leave a lot of empty paper between the circles. If you stagger them—placing the top of one circle in the gap between the two above it—you can fit more circles on the same sheet.

Automated computer software calculates the perfect layout for every sheet of coil we buy from Baosteel 6. It shifts the pattern by millimeters to get maybe 5% or 8% more lids out of the same ton of steel. In an industry where margins are tight, that 8% saving is huge. We pass that saving on to you. If we were cutting manually, we would waste much more metal, and you would have to pay for that waste.

Shielding Against Labor Inflation

Labor cost is another factor. In China, wages are rising. A factory that relies on 500 workers to pack lids by hand will see its costs go up every year. My automated line needs only two engineers to monitor it. This protects us—and you—from labor shortages and wage inflation. It allows me to offer you a stable price for the long term, even when other market costs are going crazy.

Also, consider the cost of energy. Modern servo presses use energy regeneration 7. When the press slows down, it captures that energy, similar to a hybrid car braking. Old mechanical presses just wasted that energy as heat. This lowers our electricity bill, which is another small saving that keeps your price competitive.

| Cost Driver | Traditional Factory | Huajiang Automated Factory | Benefit to Buyer |

|---|---|---|---|

| Material Usage | High scrap (Straight cutting). | Low scrap (Zig-Zag Scroll Shearing). | Lower price per unit. |

| Production Speed | ~200-400 ends/min. | 2,000+ ends/min. | Faster delivery, bulk discounts. |

| Labor Dependency | High (5-10 people per line). | Low (1-2 engineers per line). | Price stability, no labor shortage delays. |

| Energy Efficiency | Low (Old motors). | High (Regenerative drives). | Eco-friendly and cost-effective. |

How can I be sure the automated cameras detect all visual defects?

I used to trust my best quality inspectors implicitly. They were experienced and careful. But I also know that even the best human eyes get tired after an hour of staring at shiny metal. A camera never blinks, never gets tired, and never has a bad day.

Automated vision systems use high-resolution cameras and deep learning algorithms to inspect 100% of the production at line speed. These systems can detect micron-level scratches, coating voids, and ovality issues that are invisible to the naked eye, automatically rejecting any non-conforming parts without slowing down production.

The technology we use is called Machine Vision 8, but recently it has become much smarter with AI (Artificial Intelligence). In the past, a camera would just look for a dark spot on a bright lid. If there was a shadow, it might reject a good lid. Or if the scratch was light, it might miss it.

Beyond Human Vision

Today, we use deep learning. We feed the computer thousands of images of "good" lids and "bad" lids. The system learns to recognize complex defects. For example, it can tell the difference between a piece of harmless dust that will blow off and a scratch that has penetrated the coating.

The cameras are placed at multiple stages. First, we inspect the metal sheet before it is cut. If the camera sees a defect in the steel itself (like a lamination mark from the steel mill), it tells the press to "skip" that section. This prevents a bad lid from ever being made. Next, we inspect the formed end. High-speed cameras take photos of the curl, the countersink, and the rivet (for Easy Open Ends). They check for "ovality"—meaning, is the lid perfectly round? If it is slightly oval, it won’t seal properly. A human eye cannot see a 0.1mm ovality issue, but the camera can via advanced deep learning algorithms 9.

Real-Time Rejection Protocols

Finally, we inspect the compound lining. We use a specific light spectrum that makes the rubber compound glow. The camera checks the ring of compound to ensure it is continuous. If there is a bubble or a skip (a gap in the rubber), the system activates a precise air jet. This jet of air blows the bad lid off the line into a locked rejection bin. This happens in milliseconds while the line is moving at full speed.

We also use "light and pressure decay" testing for Easy Open Ends. We shine a bright light on one side of the scored line (the part you pull to open). If even a single photon of light passes through a microscopic crack, the sensor detects it. This ensures that the "score" is deep enough to open easily, but not so deep that it leaks. This balance is critical for your customer’s experience. By relying on these systems, we provide you with a Certificate of Analysis 10 (COA) that is based on real data from every single unit, not just a random sample of 100 lids picked by a tired worker.

Conclusion

Automation in our industry is not just about being fancy or modern; it is about survival and safety. For you, it means sleeping well at night knowing your production line won’t jam and your cans won’t leak. It means getting a fair price because we aren’t wasting metal. At Huajiang, we invest in these machines so you can invest your trust in us.

Footnotes

1. How automatic can seamers function in food processing lines. ↩︎

2. Understanding precision control in industrial automation machinery. ↩︎

3. Specifications and types of convenient metal packaging closures. ↩︎

4. Importance of airtight sealing for food safety and preservation. ↩︎

5. Technology for maximizing material yield in metal sheet cutting. ↩︎

6. Overview of one of the world’s largest steel producers. ↩︎

7. How regenerative braking systems save power in industrial presses. ↩︎

8. Basics of automated optical inspection in manufacturing. ↩︎

9. How AI enhances visual defect detection accuracy. ↩︎

10. Document verifying product adherence to specific quality standards. ↩︎