I know that metal packaging procurement is stressful, and you must avoid any quality issues like wavy edges. Do you worry that edge wave defects will jam your high-speed can-making line? I want to tell you how we manage this at Huajiang.

The edge wave tolerance of our Electrolytic Tin Plate (ETP) strictly follows ISO 11949 1 and GB/T 2520 standards, with maximum wave heights typically limited to $\le 0.3 \text{ mm}$ for thinner sheets ($\le 0.20 \text{ mm}$ thick) and $\le 0.5 \text{ mm}$ for thicker material ($\le 0.55 \text{ mm}$ thick), measured over a $1 \text{ m}$ length near the edge. These low tolerances are possible because we use advanced rolling and leveling processes, giving you the flat sheets you need.

You have probably dealt with bad suppliers whose material caused costly shutdowns. We want you to feel confident that our focus on precise flatness will keep your production line running smoothly and efficiently. Keep reading to see how we guarantee a flat product.

How Do I Ensure the Sheets Lay Flat to Avoid Jamming My Feeder?

I understand your frustration with jams during feeding. Nothing wastes more money than stopping a high-speed line. We must ensure the material is perfectly flat.

To ensure our tinplate sheets lay flat and avoid jamming your feeder, we use advanced process controls, including high-tech in-line shape scanning and a four-high (or higher) HC rolling mill to minimize residual stress. Our Quality Control (QC) system automatically rejects coils that do not meet our strict flatness requirements before they leave the factory.

As a procurement leader, you know flatness is key to smooth operation. The challenge is that edge wave is a result of uneven material length across the width of the strip. The edges are slightly longer than the center. This is often caused by uneven pressure during the cold rolling process 2 or uneven cooling.

Why Flatness is So Important for Can-Making

In the can-making industry, especially with high-speed machinery like lithography printers or stamping presses, sheet flatness is non-negotiable.

- Feeder Jams: Wavy edges prevent the sheets from separating cleanly in the feeder, leading to double-sheet feeds or misfeeds. This stops the line and causes expensive downtime.

- Printing Issues: If the sheet is not flat, printing registration becomes impossible 3. This leads to color misalignment and wasted printed material.

- Welding Quality: For three-piece cans, excessive edge wave can make the side seam unreliable, causing ‘fat cans’ or leaks, which is a major food safety risk for your final product. This is why we pay extra attention to the wave height on our welding-grade material.

Our Process Guarantees a Flat Product

We do not just rely on final inspection. Our flatness guarantee starts much earlier in the manufacturing process.

1. HC Rolling Mill Technology

We use an HC (Hydraulic Crown) rolling mill for the cold reduction phase. The HC mill allows us to precisely control the roll shape across the width of the steel strip. This active control system corrects the slight differences in pressure that cause uneven elongation. This means the material is processed with uniform tension and pressure across its entire width. By actively adjusting the roll gap and pressure zones, we can shape the material so that the stress is evenly distributed. This step is critical because it addresses the root cause of the waviness right at the beginning of the production line. If we do not get the shape right here, no amount of subsequent processing will fully fix it.

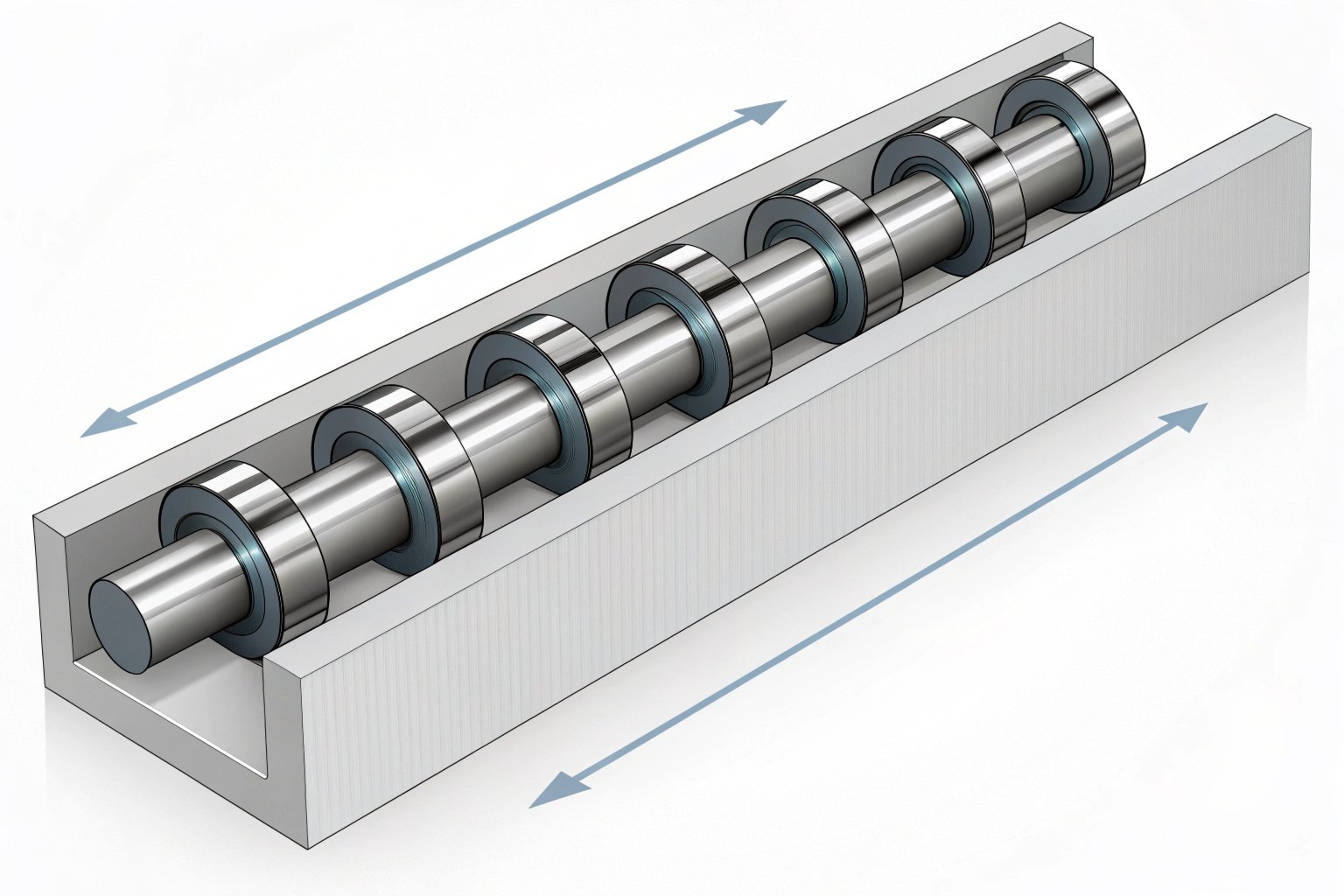

2. Tension Leveling (Shape Correction)

While the final tinplate is technically a "finished product," we can use tension leveling 4 for severe shape defects, which involves pulling the strip through a series of small-diameter rolls while under high tension.

| Process Action | Effect on Material | Benefit for Customer |

|---|---|---|

| Differential Stretching | Permanently stretches the "short" fibers (usually in the center) of the strip. | Eliminates the length difference between the center and the edge, achieving uniform flatness. |

| Stress Relief | Reduces internal stresses locked into the material during rolling. | Prevents the coil from ‘memory’ or ‘springback’ that causes waviness after uncoiling. |

| Surface Finish | Can also improve the surface for better coating and printing. | Better appearance and higher quality finished cans. |

The tension leveler applies enough stress to take the material past its elastic limit, causing permanent changes to the sheet’s structure. This is not just temporary flattening. It is permanent shape correction. When the strip leaves the leveler, all internal stresses that would cause the edge wave are gone. This capability is key to handling wide-sheet stock where flatness defects are often more pronounced. This process ensures that when your machine unrolls the material, it lies perfectly flat, reducing friction and the risk of misfeeds in your automated systems.

3. Online Shape Control and Automatic Rejection

Every single coil goes through an advanced online shape scanner after the rolling or tinning line. This system uses non-contact sensors to measure the flatness profile in real time. If the edge wave exceeds our internal standard (which is tighter than the ISO standard), the coil is automatically marked for rejection or secondary processing. Our qualified material rate is $\ge 99.9\%$. The shape scanner uses laser or air-pressure technology to map the profile of the sheet across its width hundreds of times per second. This data feeds back directly to our process control system. If the sensor detects three consecutive waves over $1 \text{ m}$ that average above the $0.3 \text{ mm}$ limit, the machine flags the coil. The material is either diverted for further leveling or classified as non-prime stock. This constant monitoring means you are protected from batch-to-batch quality fluctuations 5, which was a major frustration with your previous suppliers.

What is the Maximum Wave Height Allowed in Your QC Standard?

You need clear numbers to make a purchase decision. Vague quality claims do not help your production planning. You want to know exactly what we guarantee.

Our internal Quality Control (QC) standard for maximum wave height is more stringent than most international requirements, ensuring superior sheet performance in your stamping and seaming machines. The maximum wave height allowed is $\le 0.3 \text{ mm}$ for material thinner than $0.20 \text{ mm}$ and $\le 0.5 \text{ mm}$ for material thicker than $0.36 \text{ mm}$, with the measurement taken within $15 \text{ mm}$ of the edge over a $1 \text{ m}$ length.

Our commitment to a very low edge wave tolerance is a key reason why global can-makers choose Huajiang. The number one pain point of many can-makers like you is unexpected quality variation, which we aim to eliminate. The wave height directly translates to your risk of production issues. A $0.5 \text{ mm}$ difference can be the difference between a smooth run and a costly machine stop. We know that Carlos Gomez, as a procurement director, puts food safety and production stability first. Our tight tolerances are designed to meet that need.

Understanding the Measurement Method

We follow the standard practice but define our limits very tightly. Here is exactly how we measure the edge wave:

1. Reference Standards

We use ISO 11949 6 and GB/T 2520 as the primary standards. These standards categorize the required flatness based on the thickness of the material and the intended use (e.g., Draw & Redraw, General Canmaking). We ensure our internal limits are always inside the standard limits. For example, the ISO standard might allow for a higher wave on thicker material, but we choose to keep our internal tolerance tighter for better performance. This extra effort costs us more but saves you significant processing headaches.

2. The $1 \text{ m}$ Rule

The standard measurement requires finding three continuous wave peaks over a $1 \text{ m}$ length of the strip. The average height of these three peaks, relative to the strip’s reference line, must be below the specified tolerance. We focus on this average value because a single, isolated peak might not cause a jam, but repeated waves will. The height ($h$) is measured from the lowest point (trough) to the highest point (peak) of the wave over a set length ($L$). If the ratio $h/L$ gets too high, the material will not feed or print correctly. By averaging three peaks, we get a reliable measure of the overall "waviness" of that section. This gives us a better picture of the material’s true shape than just looking at the single worst point.

3. Welding Grade Material Exception

For special materials used in high-speed welding (like for chemical cans or aerosol cans), we apply an even stricter standard. For these products, we require the wave height within $5 \text{ mm}$ of the strip edge to be $\le 0.25 \text{ mm}$. This tiny tolerance is essential for a stable welding current and a perfect seam. The welding process for three-piece cans uses an electrical current that relies on consistent contact between the material edges. If the edge has even minor waviness, the gap between the overlaps changes. This leads to inconsistent welding strength, which is a major food safety risk 7 and can cause the canned product to fail later. Our specialized measurement ensures the surface is nearly perfect near the edge.

Huajiang’s Tolerance Table (Example)

| Thickness Range (mm) | Temper Grade | Max Edge Wave Height ($h$) | Max Wave Height Distance from Edge | Reference Standard |

|---|---|---|---|---|

| $0.12 \sim 0.20$ | T-3, T-4 | $\le 0.30 \text{ mm}$ | $15 \text{ mm}$ | ISO 11949 / GB/T 2520 |

| $0.20 \sim 0.36$ | T-4, DR-8 | $\le 0.40 \text{ mm}$ | $15 \text{ mm}$ | ISO 11949 / GB/T 2520 |

| $0.36 \sim 0.55$ | T-5, DR-9 | $\le 0.50 \text{ mm}$ | $15 \text{ mm}$ | ISO 11949 / GB/T 2520 |

When you place an order, our technical team will always confirm the specific wave tolerance for your product, ensuring we meet your machinery’s exact needs. We always try to beat the standard to give you the highest performance. We understand that your stamping and welding equipment may have tighter tolerances than the general industry standards. This table represents our minimum guarantee; we often achieve even flatter results.

Do you use tension leveling to correct shape defects?

Shape defects are the biggest headache in flat-rolled products. I know that if you buy a coil with shape defects, you will spend money trying to fix them or scrap the material. You must know if your supplier has the technology to fix these issues.

Yes, we use tension leveling 8 as a proven, corrective process to permanently eliminate shape defects such as edge wave and center buckle from our electrolytic tin plate. This mechanical process equalizes the internal length differences in the steel strip, which is the root cause of these defects. This is a critical step in our process to ensure the flatness required by your high-speed canning lines.

Tension leveling is not a standard process for every tinplate supplier. Some factories skip it or only use it for high-cost special materials. However, at Huajiang, we see it as a key tool to guarantee our material quality. We understand that your profitability depends on zero defects. A single day of downtime from bad material can wipe out months of profit. Tension leveling is an investment we make to protect your production schedule. It is this dedication to upstream quality control 9 that separates us from suppliers who only focus on low price.

The Science Behind Tension Leveling

A "shape defect" is simply a sign that the material has internal stress that causes it to become wavy or buckle. Tension leveling uses controlled force to fix this. The material itself is slightly elastic, meaning it can be stretched a little and go back to its original shape. However, tension leveling pushes the material beyond that elastic point.

1. Plastic Deformation

The strip is simultaneously pulled (under high tension) and bent over small-diameter work rolls. This combined action causes a slight plastic (permanent) deformation of the steel. The parts of the strip that are "shorter" (like the center in an edge wave defect) are stretched just enough to match the length of the "longer" parts (the edges). This permanent stretching means the defect cannot reappear later. The process precisely controls the amount of stretching so the material thickness is not affected.

2. Full-Width Correction

The key benefit is that the entire width of the strip is corrected in one pass. It permanently "re-programs" the internal structure of the material, which means the flatness correction lasts even when you cut the coil into sheets. This is much better than simple roller leveling, which only temporarily flattens the material. Simple roller leveling only bends the material, which might temporarily hide the wave, but the internal stresses remain. When you cut the coil, those stresses are released, and the defect returns. Tension leveling removes the stress completely.

| Defect Type Corrected | Cause of Defect | Why Tension Leveling Fixes It |

|---|---|---|

| Edge Wave | Edges are longer than the center. | Stretches the center to match the edge length. |

| Center Buckle | Center is longer than the edges. | Stretches the edges to match the center length. |

| Oil Canning | Random, non-uniform length variation across the width. | Stretches all areas uniformly to eliminate internal length differences. |

This table shows exactly how the process directly addresses the different types of shape problems. The result is a sheet that has zero residual stress. This stress-free material performs much better in your high-speed stamping dies and printing presses, ensuring your expensive tools last longer and produce better quality.

Tension Leveling in the Huajiang Flow

Our $600$-acre facility has state-of-the-art rolling and finishing lines. Tension leveling is fully integrated before the final tinning process. By using it, we ensure that the base steel strip is perfectly flat before the tin layer is applied. This means the final product has perfect shape and a perfect coating. We do not just make tinplate; we engineer flatness. We have 53 lines, including advanced coating and printing lines, which benefit from the flatness achieved by tension leveling. If the material is not perfectly flat when it enters the printing press, the $4$- to $6$-color printing will be misregistered, leading to a massive loss of high-value stock. This is why we insist on this expensive, quality-driven step for all our metal packaging materials.

Can I reject the coil if the center buckle is too severe?

Your procurement policy must have a clear procedure for rejecting non-conforming material 10. When you buy large quantities of steel, you need to know that we will stand behind our quality standards.

Yes, you can reject the coil if the center buckle or any other shape defect exceeds the contractually agreed-upon tolerance. At Huajiang, we guarantee that all supplied coils meet the flatness standards outlined in ISO 11949 and GB/T 2520, which cover severe defects like center buckle. We have a clear policy for quality claims and will not push back if the material is demonstrably outside of the accepted commercial standards.

As a large-scale manufacturer, we believe in taking full responsibility for our product. You, as the buyer, should never have to suffer a loss due to a supplier’s quality failure. Carlos Gomez often deals with the pressure of securing high-quality material for critical harvest seasons. We know a late or faulty shipment can cause raw ingredients to spoil, leading to immense financial damage. Our commitment is to eliminate that risk.

Defining Center Buckle

Center buckle is the opposite of edge wave. In this case, the center of the strip is longer than the edges, causing the strip to pucker or buckle in the middle. Like edge wave, it is a non-uniform elongation defect. Center buckle usually shows up as waves or folds in the center of the sheet.

If the center buckle is too severe, the sheet may not feed, and the defect can carry through into the finished can, causing:

- Lid Defects: Center buckle on EOE (Easy-Open Ends) or Normal Ends stock leads to poor forming and can result in bad seals. The high-speed press cannot form a perfect seal with puckered material.

- Wasted Material: You will have to cut out the buckled sections of the coil, leading to massive material loss. If the buckle is severe, an entire coil might be unusable for sensitive applications.

The maximum wave height for center buckle is often treated the same way as edge wave in terms of $\text{mm}$ over $1 \text{ m}$ length. A severe center buckle is defined as one that causes the sheet to lift more than the specified height, typically $0.5 \text{ mm}$ or more, in the middle of the strip.

Our Policy on Rejection and Claims

We aim for perfection, but when a defect happens, we handle it quickly and professionally.

1. Clear Standards are the Basis

Your purchase order references a specific technical data sheet (TDS). This document clearly states the maximum allowed wave height and the limits on other defects. Any material exceeding these limits is non-conforming. We provide all necessary SGS and FDA compliance reports, which confirm our adherence to these standards. This documentation provides you with the immediate evidence needed to process a claim.

2. The Huajiang Guarantee

Unlike some smaller suppliers, we have the financial strength and reputation to handle any quality claim immediately. If you provide verifiable evidence (photos, measurement reports) that a coil has a severe center buckle or edge wave beyond tolerance, we commit to:

- Immediate Inspection: Sending a technical expert to your site for joint inspection if necessary. Our staff understands technical terms like sulfur resistance test and coating integrity.

- Clear Resolution: Providing replacement material fast, or issuing a credit note for the faulty material. We want long-term partners, not one-time customers. Our policy is clear: if the quality is our fault, we take the loss.

Our large, ready-to-ship stock of nearly $100,000 \text{ tons}$ of coil and sheet material ensures that we can quickly replace any non-conforming batch during your busy season. This means you avoid the costly delays that ruined your experience with previous suppliers.

Conclusion

We guarantee the flatness of our ETP with a strict standard, $\le 0.3 \text{ mm}$ for thin gauges, backed by advanced HC mills and tension leveling. We stand by our promise, and any non-conforming material can be rejected.

Footnotes

1. Review the official ISO standard for cold-reduced electrolytic tinplate. ↩︎

2. Technical explanation of the cold rolling process and its effects on metal shape. ↩︎

3. Learn why sheet flatness is crucial for perfect printing and lithography registration. ↩︎

4. Academic study on how tension leveling permanently corrects strip shape defects. ↩︎

5. Introduction to Statistical Process Control (SPC) for managing material quality variations. ↩︎

6. Direct link to the international specification for tinplate shape and tolerance. ↩︎

7. Official FDA guidance on can defects and their link to food safety in packaged goods. ↩︎

8. Detailed technical paper on the mechanics and application of tension leveling technology. ↩︎

9. Textbook explanation of the principles of quality control in a manufacturing environment. ↩︎

10. Guide to best practices for handling and rejecting non-conforming supplier materials. ↩︎