I’ve often pondered the intricacies of can manufacturing, especially the efficiency of scroll-cut ETP sheets over traditional rectangular ones. There’s a clear potential to save material and reduce waste.

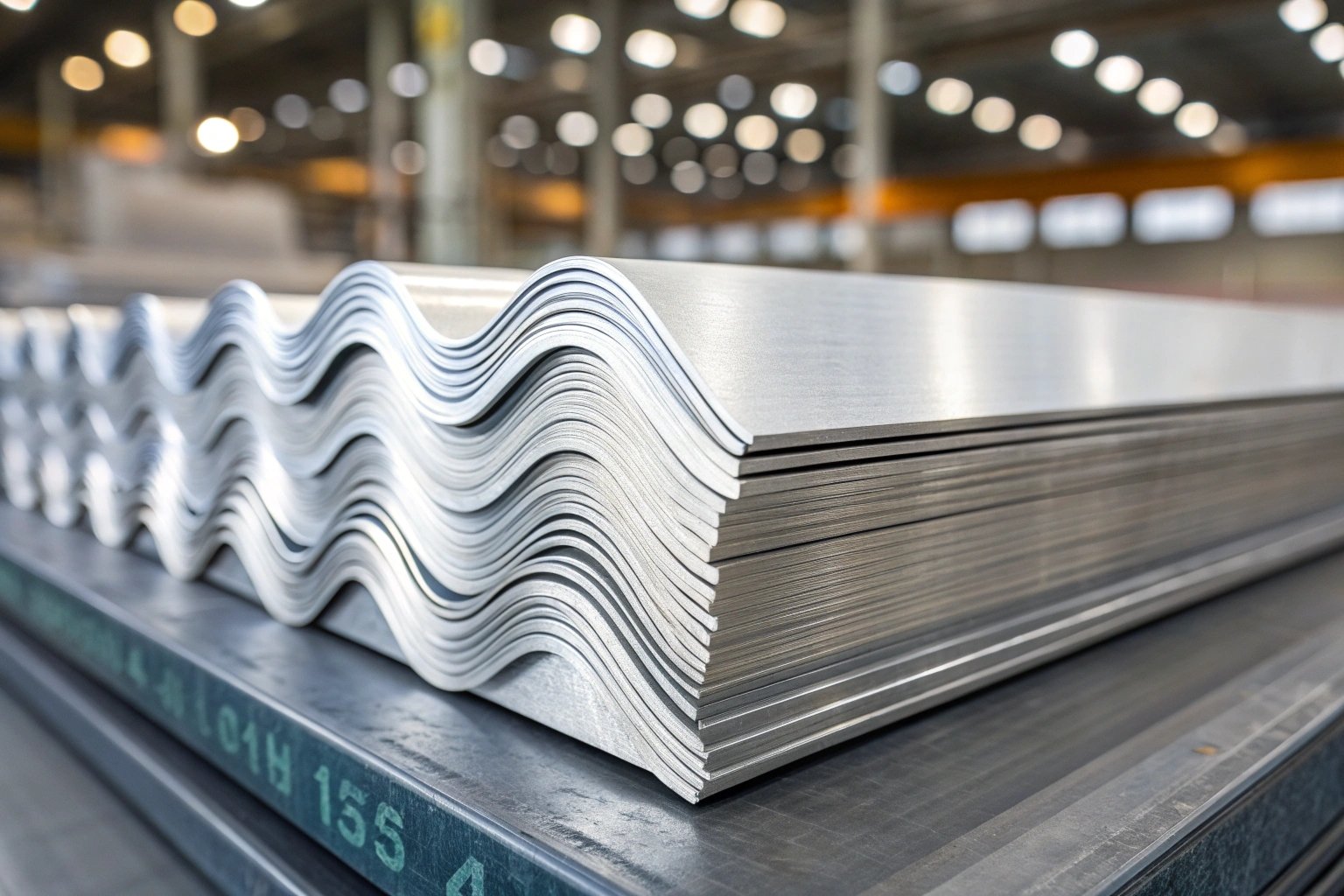

Scroll-cut Electrolytic Tin Plate 1 sheets are specifically crafted for can manufacturers 2 to maximize material usage and minimize scrap. By precisely matching the scroll-shearing pattern to can layouts, manufacturers achieve a high yield of usable content, boosting efficiency.

So what makes scroll-cut ETP sheets a preferable choice? They significantly reduce waste and improve material utilization by ensuring each sheet is perfectly cut for specific can sizes and shapes. This precision aids in streamlined production processes.

How much material can I save by using scroll-cut sheets vs. rectangular sheets?

How does scroll-cutting optimize material savings? It’s a question that has intrigued me, given the traditional reliance on rectangular sheets.

Scroll-cutting creates a wave-pattern cut that allows for tighter nesting of circular can ends. This method reduces scrap waste 3 significantly compared to straight cutting, increasing yield and decreasing costs.

Scroll-cut sheets provide substantial material savings by strategically aligning the cut with the circular ends of the cans. Material utilization 4 improves as can ends are closely nested, minimizing unused scraps. Manufacturers have observed that, on average, scroll cutting can reduce waste by up to 10-15% compared to using conventional rectangular sheets. This efficiency not only boosts savings but also supports environmental sustainability 5 by minimizing resource use.

Material Utilization Table

| Cutting Method | Material Savings | Scrap Reduction Rate |

|---|---|---|

| Scroll-Cut Sheets | Up to 15% | Significant |

| Rectangular Sheets | Negligible | Standard |

Can you customize the scroll pattern for my specific can end diameter?

I’ve always been fascinated by the level of customization scroll cutting can offer. Tailoring the scroll pattern to fit exact specifications is a challenge worth exploring.

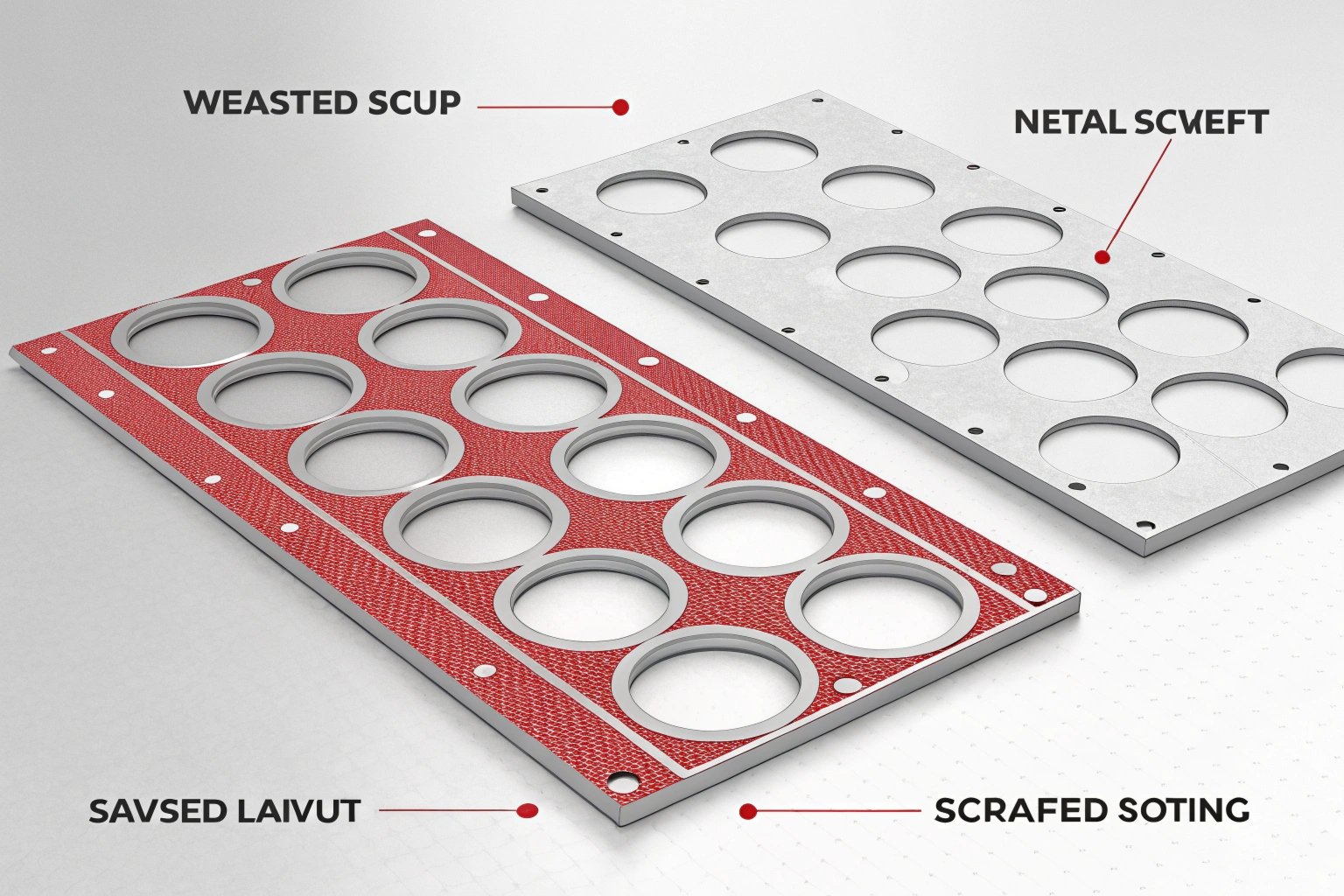

Customization allows manufacturers to align the scroll pattern precisely with specific can sizes. This adaptability enhances production efficiency 6 and product consistency 7.

Scroll cutting accommodates specific can dimensions and diameters. By customizing the scroll layout, manufacturers ensure the cut matches the exact size required for can ends, lids, or closures. Tooling adjustments enable tailored solutions that align the scroll pattern to unique specifications, minimizing waste and enabling seamless production integration. Manufacturers often conduct an initial assessment of the can dimensions to ensure precision, resulting in enhanced manufacturing performance and product compatibility.

Customization Options Table

| Scroll Feature | Customization Level | Benefits |

|---|---|---|

| Pattern Size | High | Reduced Waste |

| Tooling Adjustments | Specific | Precision Fit |

Do you charge extra for the scroll-shearing service?

The question of additional costs for scroll-shearing service is one that frequently crosses my mind, as financial efficiency plays a critical role in manufacturing.

Charging for scroll-shearing depends on various factors, including volume and complexity. Service fees are assessed to cover tooling and labor involved.

Scroll-shearing services may incur extra charges based on the intricacy of the scroll pattern required and the volume of production 8. More complex cuts or customized patterns necessitate specialized tooling 9 and may add to service costs. However, manufacturers often provide pricing tiers based on quantity, allowing flexibility and potential cost-sharing for larger orders. It’s advisable to clear any concerns of hidden fees upfront by obtaining detailed quotations based on the specific can dimensions and production requirements.

Service Cost Considerations Table

| Cost Factor | Basis for Charge | Notes |

|---|---|---|

| Complexity | Higher for intricate patterns | Custom Tooling Needed |

| Volume | Discount on bulk orders | Economies of Scale |

How do I ensure the scroll layout fits my punch press feed?

Adjusting the scroll layout to fit existing punch press systems seems like a daunting task, yet possible with meticulous planning.

Ensuring compatibility involves precise alignment of the scroll pattern with the punch press to facilitate smooth feeding and operation.

To guarantee that the scroll layout fits your punch press 10 feed, careful attention to the machine’s specifications is essential. Begin by verifying the punch press dimensions and capabilities to tailor the scroll cut accordingly. Manufacturers can provide custom scroll dies that match the press’s specific needs, ensuring seamless integration into existing setups. Additionally, conducting trial runs or mock-ups can further assist in confirming the fit and performance. Collaborative efforts between manufacturers and equipment providers facilitate efficient alignment and operational success.

Punch Press Compatibility Checklist

| Compatibility Factor | Action Required | Benefits |

|---|---|---|

| Press Dimensions | Verify specifications | Seamless Integration |

| Scroll Die Fit | Tailor to press capabilities | Enhanced Performance |

Conclusion

Understanding scroll-cut ETP sheets opens up possibilities for enhanced efficiency and customization in can manufacturing. Exploring these options brings significant value.

Footnotes

1. Definition and industrial applications of tinplate steel. ↩︎

2. Trade association resources for the can manufacturing industry. ↩︎

3. EPA guidelines on reducing industrial scrap and waste. ↩︎

4. Engineering principles for optimizing raw material usage. ↩︎

5. Global goals for sustainable consumption and production patterns. ↩︎

6. Economic definition of maximizing output with minimal waste. ↩︎

7. ISO standards regarding consistent quality management systems. ↩︎

8. Explanation of how production volume impacts cost efficiency. ↩︎

9. Overview of custom tool and die making processes. ↩︎

10. Technical specifications and operations of punch press machinery. ↩︎