You found a great price on tinplate, but there is a problem. The supplier only sells massive master coils, and your production line cannot handle them. You are stuck looking for a third-party processor, adding cost and delay to your project. I know how frustrating this gap in the supply chain 1 can be for a busy production manager.

Yes, at Huajiang, we provide precise slitting services for all our Electrolytic Tin Plate (ETP) coils. We can cut master coils into the exact strip widths you need, from wide sheets down to narrow strips as small as 6mm, directly in our factory before shipment.

This service saves you time and money. You do not need to move heavy steel between a warehouse and a service center. We handle everything under one roof. We take the raw coil from our stock, slit it to your specifications, pack it securely, and ship it straight to your factory. This ensures the Electrolytic Tin Plate 2 is ready for your machines the moment it arrives.

How precise is your slitting tolerance for narrow strips?

When your production line runs at high speeds, even a tiny variation in width can cause a jam. I have seen entire shifts stopped because a strip was half a millimeter too wide. You cannot afford that kind of downtime.

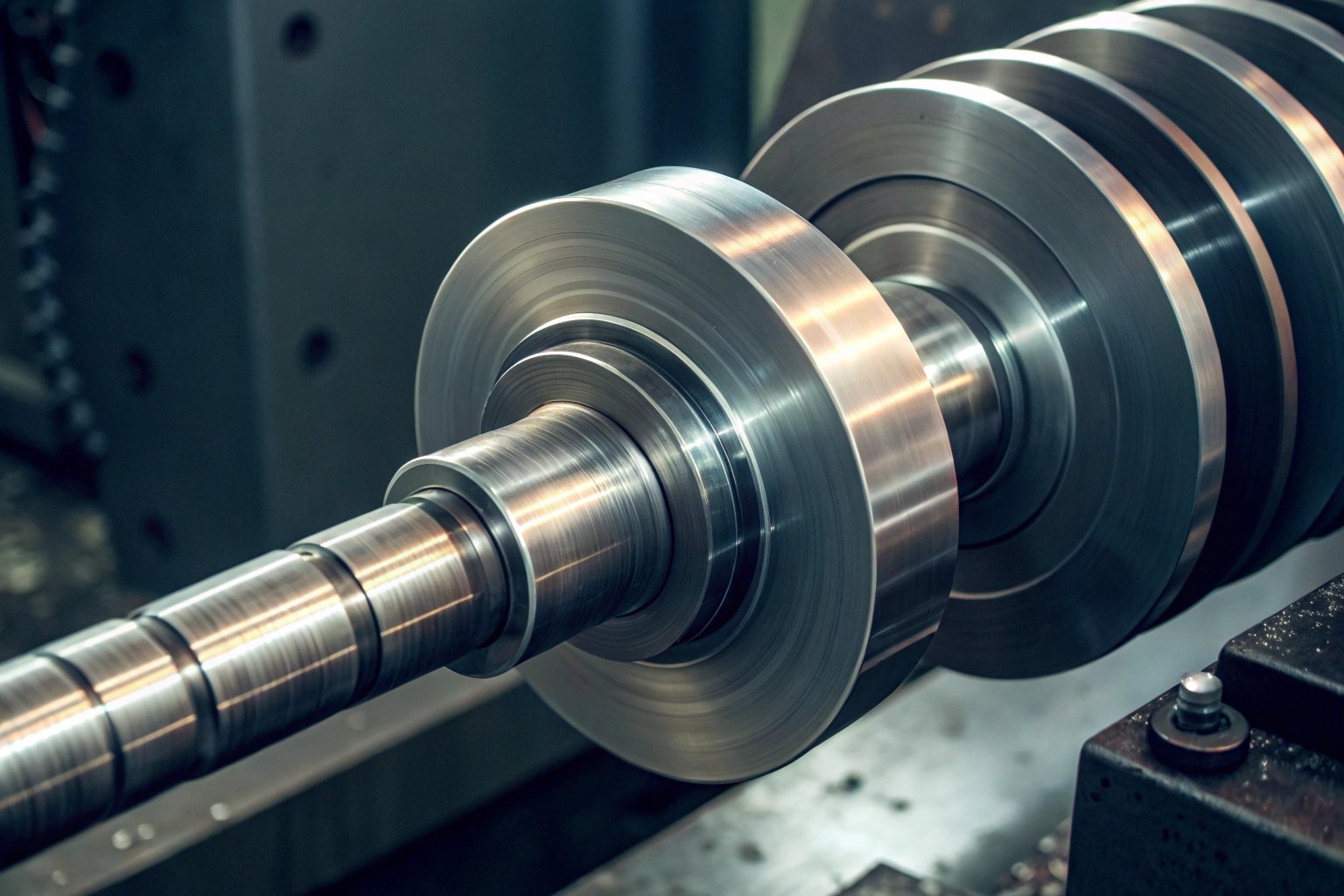

We control our slitting width tolerance strictly within ±0.05 mm for most applications. Using advanced rotary shear slitting lines and high-precision tooling, we ensure that every meter of the strip maintains a consistent width from the start of the coil to the end.

Precision is not just about having a sharp knife; it is about the entire system. In the metal packaging industry, especially when making components like Easy Open Ends 3 (EOE) or twist-off caps, the margin for error is almost zero. If the strip is too wide, it jams the guides in your punch press. If it is too narrow, you get "short shots" or incomplete parts.

At Huajiang, we use shimless tooling 4 technology. Old-fashioned slitters use plastic shims to set the width, which can compress and change size over time. Our modern setup uses computerized steel spacers that do not change shape. This guarantees that the width we set is the width you get.

We also focus heavily on tension control. Tinplate is thin and soft. If the tension on the rotary shear 5 slitting line is not perfect, the steel can stretch or "neck down," changing its width. Our lines use automated tension braking systems that adjust in real-time. Whether we are cutting 0.15mm ultra-thin material or 0.50mm thick steel, the machine keeps the metal flat and true.

Here is a look at the typical tolerances we achieve compared to standard market norms:

Table 1: Huajiang Slitting Tolerance Capabilities

| Material Thickness (mm) | Standard Market Tolerance (mm) | Huajiang Precision Tolerance (mm) | Typical Application |

|---|---|---|---|

| 0.15 – 0.25 | ± 0.10 | ± 0.03 | Battery tops, Aerosol cones |

| 0.26 – 0.40 | ± 0.15 | ± 0.05 | Beverage ends, Crown caps |

| 0.41 – 0.60 | ± 0.20 | ± 0.08 | Industrial can rings, Brackets |

By holding these tight tolerances, we help you reduce scrap. You do not have to trim the edges again at your factory. You can feed our coils directly into your presses, increasing your yield and keeping your machines running smoothly.

Can you slit the coils into multiple baby coils for my production line?

Handling a 10-ton master coil is dangerous and difficult if your facility is not equipped for it. Many specialized production lines, specially for making lids or electronic parts, are designed for smaller, lighter coils. You need material that fits your machine, not the other way around.

We can absolutely slit master coils into multiple "baby coils" to fit your specific weight and dimension requirements. We can control the Outer Diameter (OD) and the weight of each small coil to match the capacity of your uncoilers.

The term "baby coil" sounds small, but it represents a big logistical advantage for many of our clients. A standard master coil from a steel mill like Baosteel 6 or Shougang weighs between 6 to 12 metric tons. While this is efficient for shipping, it is a nightmare for a factory with 3-ton forklifts or light-duty decoilers.

When we process your order, we look at your equipment limitations. If your uncoiler can only hold 2,000 kg, we stop the winding process exactly at that weight and cut the sheet. We then restart the line for the next coil. We can also split a wide coil into several narrow strips simultaneously. For example, we can take a 1000mm wide master coil and turn it into ten separate 100mm wide baby coils.

Storage and handling of these narrow coils require special care. Narrow coils are unstable; they can tip over like dominoes if not packed correctly. We use Eye-to-Sky packaging 7 (vertical axis) for these orders. This means the coils are stacked flat on a pallet, looking like a stack of donuts. This prevents them from rolling and makes them easy to lift with a forklift or a crane hook.

We also pay attention to the Inner Diameter (ID). Standard IDs are usually 420mm or 508mm. If your machine requires a specific ID to fit the expansion mandrel, let us know. We have different sleeves to adjust the winding drum size.

Table 2: Baby Coil Specification Options

| Feature | Standard Master Coil | Custom Baby Coil Options |

|---|---|---|

| Coil Weight | 6,000 – 12,000 kg | 500 – 3,000 kg (Customizable) |

| Inner Diameter (ID) | 508 mm | 420 mm / 508 mm |

| Outer Diameter (OD) | 1,200 – 1,600 mm | Max 1,600 mm (Limited by weight) |

| Packaging Orientation | Horizontal (Eye-to-Wall) | Vertical (Eye-to-Sky) or Horizontal |

This flexibility allows you to buy in bulk for the best price, but receive the material in a format that your shop floor team can actually handle safely.

Do you inspect the burr height on the slit edges?

Nothing ruins a can’s integrity faster than a sharp metal burr. If the edge of your slit strip is rough, it will scratch the protective lacquer on the next layer of the coil. This leads to rust, contamination, and eventually, a leaking can that destroys your brand’s reputation.

We inspect burr height on every slit edge using online monitoring and offline microscopic checks. Our standard maximum burr height is less than 5% of the material thickness or 0.03mm, ensuring the edges are smooth and safe for coating.

Let’s dig into why this matters so much. Slitting is a shearing process. The upper and lower knives cut the metal like a pair of scissors. If the gap between the knives is too wide, the metal tears instead of cutting cleanly. This tearing creates a "burr"—a sharp, raised ridge of metal along the edge.

In the canning industry, burrs are enemies. First, they are sharp. They can slice through the delicate protective varnish or PET film on the tinplate. Once the coating is broken, the steel is exposed to the contents of the can. If you are packing acidic food like tomatoes or pineapple, the acid will attack that exposed steel immediately. This causes hydrogen gas 8 to build up inside the can, leading to "swollen" or "blown" cans on the supermarket shelf.

Second, burrs affect the mechanics of can making. When you form the can body or the lid, the metal has to flow and bend. A burr acts like a stress concentrator. It can cause the metal to crack during the flanging or seaming process.

At Huajiang, we manage this with strict maintenance protocols. We sharpen our tungsten carbide 9 knives regularly. We do not wait for them to get dull. Before every production run, our operators calculate the precise knife clearance based on the thickness of your tinplate. Thinner plates require a tighter gap.

During the run, we stop and measure. We use a digital microscope to measure the height of the burr. If it exceeds our limit, we stop the line and reset the knives. We verify the quality so you do not have to worry about scratches or tool damage on your end.

Table 3: Burr Height Impact and Standards

| Burr Height | Risk Level | Consequence | Huajiang Standard |

|---|---|---|---|

| < 0.01 mm | Low | Safe for high-quality printing and coating. | Target Zone |

| 0.02 – 0.03 mm | Medium | Acceptable for general industrial use. | Acceptable Limit |

| > 0.05 mm | High | Scratches lacquer; causes corrosion and die wear. | REJECTED |

Is the slitting cost included in the price per metric ton?

Pricing in the steel industry can be confusing, with hidden surcharges appearing on the final invoice. You need to calculate your exact cost per unit to know if your product will be profitable. You need a clear answer on how we charge for processing.

The slitting cost is usually a separate processing fee added to the base price of the tinplate, or we can offer an "all-in" price per metric ton. The cost depends on the complexity of the job, such as the number of cuts and the amount of scrap generated.

Transparency is key to our partnership. When we talk about the price of slit coils, there are three main factors you need to understand: the labor fee, the packaging fee, and the "yield loss."

First, the labor fee covers the machine time and electricity. If you want a wide coil cut into two halves, the machine runs fast, and the cost is low. If you need a coil cut into twenty narrow strips, the machine runs slower, and the setup time is longer. Therefore, narrow strips cost slightly more to process than wide strips.

Second is the yield loss 10 or scrap. To get a clean edge, we have to trim a few millimeters off both sides of the master coil. This is called the "edge trim." If we take a 1000mm coil and you need 980mm of usable product, that 20mm of waste is scrap. Since we buy the master coil by weight, that scrap is metal we paid for but cannot sell as prime product. Usually, the price is calculated based on the incoming weight (Gross Weight) or the price is adjusted higher to cover the scrap loss on the outgoing weight (Net Weight).

We prefer to be upfront. We can give you a quote that says, "Base Price + Slitting Fee." Or, if you prefer simplicity, we can give you a final "Net Weight Price" that includes everything. This way, you know exactly what you are paying for every ton of usable material that lands on your dock.

We also save you money in hidden ways. By buying slit coils from us, you do not pay freight for the scrap metal. You do not pay to ship the waste edges from China to your country, only to throw them away. You only pay to ship the metal you actually use.

Conclusion

At Huajiang, we do more than just sell steel; we prepare it for your success. Whether you need tight tolerances for high-speed lines, manageable baby coils for specific machinery, or burr-free edges for food safety, we have the technology to deliver. We take the complexity out of the supply chain so you can focus on manufacturing.

Footnotes

1. Definition and comprehensive explanation of supply chain management logic. ↩︎

2. Technical specifications and uses of Electrolytic Tin Plate (ETP). ↩︎

3. Overview of Easy Open Ends (EOE) for metal packaging. ↩︎

4. Benefits of shimless tooling for precision metal slitting. ↩︎

5. Engineering principles behind rotary shear mechanisms in manufacturing. ↩︎

6. Official site of Baosteel, a leading global steel manufacturer. ↩︎

7. Best practices for packaging and handling heavy metal coils. ↩︎

8. Chemical properties of hydrogen causing reactions in canned goods. ↩︎

9. Properties of tungsten carbide used in industrial cutting tools. ↩︎

10. Understanding yield variance and loss in manufacturing processes. ↩︎