I know the frustration of dealing with material suppliers who do not understand the specific demands of cap manufacturing, leaving you worried about production stops or quality claims.

Yes, we supply Electrolytic Tin Plate specifically designed for twist-off caps. Our material meets FDA and EU standards, featuring optimized tempers like T3 and DR8, along with customized tin coating weights to ensure secure vacuum sealing and excellent corrosion resistance.

I have worked in this industry for over 27 years, and I want to share the technical details that matter most to your business.

Is your tinplate strong enough to form the lugs without cracking?

I understand that if a lug cracks during the capping process, it is not just a small defect; it destroys the vacuum seal 1 and ruins your product’s safety.

Our tinplate uses MR and SPCC grade steel with strictly controlled ductility and temper ranges (T3-T4). This balance ensures the metal can withstand the sharp bending required to form lugs without micro-cracking, keeping the protective varnish intact.

Understanding Lug Strength and Formability

When we talk about the strength of the lugs on a twist-off cap, we are discussing a very specific balance in the properties of the steel. If the steel is too soft, the lugs will bend out of shape when the capping machine applies pressure. This means the cap will not grip the glass jar tightly enough, and the jar will leak. On the other hand, if the steel is too hard or brittle, the lugs will snap or develop tiny cracks when they are formed. In our factory in Fujian, we manage this by strictly controlling the "Temper" and the "Grain Structure" of the steel.

For most standard twist-off caps (RTO), we recommend a T3 temper. This has a hardness level of roughly 57 on the HR30T scale 2. This level provides the necessary stiffness to hold the vacuum seal but keeps enough flexibility to bend without breaking. For customers who want to save money by using thinner metal, we use Double Reduced (DR) materials like DR8. However, working with DR materials is harder because the grain of the metal is very directional.

We pay close attention to the anisotropy 3 of the metal. This is a technical word that describes how the metal stretches in different directions. If this is not balanced, you will get earing 4. This looks like wavy or uneven edges on the cap skirt. If the edge is uneven, the lugs will not be at the same height, and the seal will fail. We ensure our rolling process minimizes this variance so every cap is perfectly round.

We also use specific steel grades like MR (Low Residual). This steel has fewer impurities like phosphorus or silicon. Fewer impurities mean the steel is cleaner and less likely to break under stress. This allows your machines to run at high speeds without tearing the metal.

Here is a simple guide to how we choose the right hardness for your caps:

| Cap Application | Recommended Temper | Hardness (HR30T) | Why we use this? |

|---|---|---|---|

| Regular Twist-off (RTO) | T3 (TH57) | 57 ± 3 | Good balance of stiffness and bending. |

| Deep Twist Open (DTO) | T2.5 – T3 | 55 – 57 | Softer metal for deeper shapes. |

| Cost-Optimized Caps | DR8 (DR550) | 73 ± 3 | Very strong, allows for thinner sheets. |

Do you have a PVC-free adhesive lacquer for the cap liner?

I know that food safety rules in Europe and North America are changing fast, and you cannot afford to have your products blocked because of non-compliant materials.

We offer advanced PVC-free lacquer systems that work perfectly with our tinplate surfaces. These coatings meet strict FDA and EU regulations, ensuring safe contact for food while maintaining a strong bond with the sealing compound.

The Shift to PVC-Free Solutions

The packaging world is moving away from Polyvinyl Chloride 5 because of health concerns about the chemicals used to make it soft. However, for a manufacturer like you, switching to PVC-free materials is difficult. PVC was very good at sticking to metal. When you remove it, you often face a problem called "adhesion failure." This is when the rubbery sealing compound inside the cap peels off the metal. If this happens, the jar is not safe.

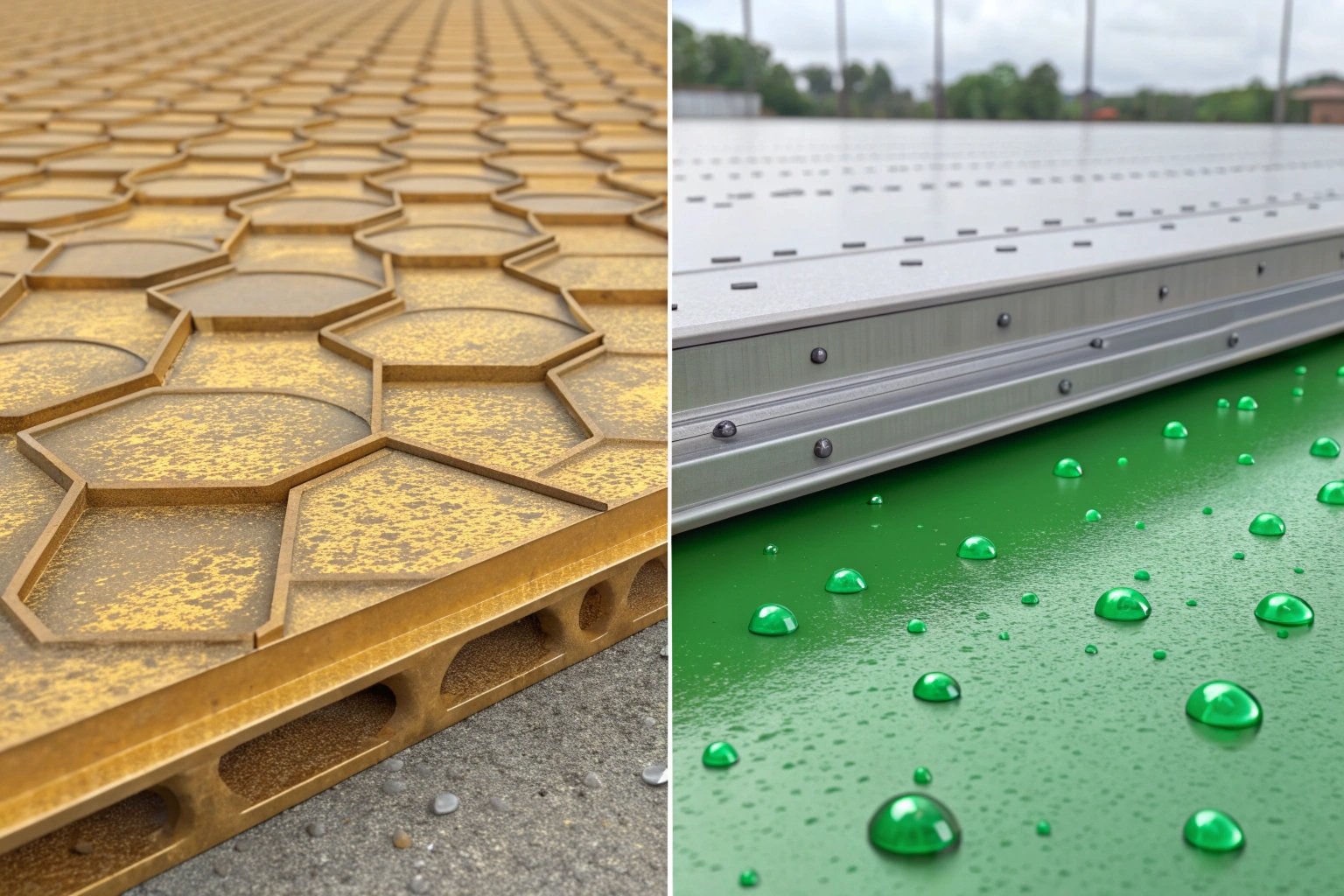

I help my clients solve this problem by looking at the surface of the tinplate itself. You cannot just apply a PVC-free lacquer to a smooth, shiny surface and expect it to hold. It is too slippery. We supply tinplate with a "Stone" or "Fine Stone" surface finish. This finish is rougher than the standard bright finish. It has a texture like a very fine stone. This roughness creates more surface area for the lacquer and the sealing compound to grab onto. It acts like thousands of tiny anchors.

We work with the best coating suppliers to apply special internal coatings. These are often made of polyester or other safe materials. They are free from BPA derivatives 6 and PVC. But applying the coating is only half the battle. The coating must pass the "sterilization test." We simulate your canning process in our lab. We heat the material to 121°C for 60 minutes. We check to make sure the lacquer does not bubble, turn white, or peel off.

Also, the lacquer must be flexible. Many caps have a "safety button" in the middle that pops up when the jar is opened. This button moves up and down. The coating must move with the metal. If the coating is brittle, it will crack when the button moves. This exposes the bare steel to the food, which causes rust.

Below is a comparison of the coating systems we can apply to your tinplate:

| Coating Type | Contains PVC? | Flexibility | Adhesion to Compound | Typical Use |

|---|---|---|---|---|

| Traditional Organosol | Yes | High | Excellent | General Food Jars |

| Epoxy-Phenolic | No | Medium | Good | Acidic Foods |

| Polyester (PVC-Free) | No | High | Excellent (w/ Stone Finish) | Baby Food / EU Export |

Can you supply the material in strips ready for cap making?

I see how much metal is wasted when you cut circles out of square sheets, and it hurts to see your money ending up as scrap metal.

We provide high-precision scroll-cut sheets and strips that are designed for making circular caps. This zigzag cutting pattern significantly reduces waste, saving you approximately 4% to 8% in raw material costs compared to using standard rectangular sheets.

Saving Money with Scroll Shearing

In the metal packaging business, the cost of the steel is your biggest expense. If you buy standard rectangular sheets and cut circles out of them, you leave a lot of unused metal between the circles. We call this "web scrap." To fix this, we use a method called scroll shearing 7.

Scroll shearing cuts the edge of the metal sheet in a wave shape or a zigzag pattern. This allows the circles (the caps) to fit closer together when you stamp them out. Imagine you are cutting cookies from dough. If you arrange them in a honeycomb pattern, you fit more cookies on the tray. By doing this primary scroll cutting at our factory in Fujian, we get more caps out of every ton of steel.

We keep a large stock of 100,000 tons of coil from top steel mills like Baosteel. This allows us to pick the exact width of coil that matches your cap size. We process this through our Fuji coating lines and then cut it into scroll sheets that are ready for your press.

Buying in strips or scroll sheets also helps your cash flow. You do not pay for the scrap metal that you would just throw away. Also, it speeds up your factory. Your workers do not have to cut the sheets themselves. They can load the strips directly into the cap-making machines.

We also use special packaging for these strips. Because the edges are exposed, they can rust easily during ocean shipping. We use Vapor Corrosion Inhibitors 8 (VCI) in our wooden skids. This releases a gas that protects the metal from rust while it travels to your factory in Mexico or Spain.

Here is why scroll cutting is a smarter choice for your budget:

| Feature | Straight Cut Sheet | Scroll Cut / Strips |

|---|---|---|

| Material Usage | 78% – 82% | 85% – 90% |

| Scrap Rate | High | Low |

| Shipping Cost | Pays for waste weight | Pays for usable metal only |

| Production Speed | Slower (needs shearing) | Faster (press ready) |

What coating weight is best for acidic pickle jars?

I know that acid is the worst enemy of metal, and nothing damages a brand reputation faster than a customer finding rust on the inside of a pickle jar.

For high-acid foods like pickles, we recommend a heavier tin coating weight of 5.6/5.6 g/m² or a differential coating of 5.6/2.8 g/m². This creates a strong barrier against corrosion, especially when combined with our acid-resistant epoxy-phenolic lacquer systems.

Protecting Metal from Aggressive Foods

Pickles, vinegar, and tomato sauces are very aggressive to metal. They contain acids and salts. These act like electrolytes in a battery, which speeds up rust. If the coating on the inside of the cap fails, the acid attacks the steel. This causes hydrogen gas to form. This gas can break the vacuum seal of the jar. This leads to "false spoilage," where the jar looks bad even if the food is okay, or it allows real bacteria to grow.

To stop this, we use a double-protection strategy. First, we increase the amount of tin on the steel. Standard caps usually use 2.8 g/m² of tin. For pickles, we double this to 5.6 g/m² on the side that touches the food. Tin is naturally good at resisting organic acids. It acts as a sacrificial layer that protects the steel underneath.

Second, we use a special lacquer. We recommend an aluminized or gold epoxy-phenolic 9 lacquer. This type of paint is very dense. It is "cross-linked," which means the molecules are tied tightly together. Acid molecules cannot easily pass through it. We check this using an Enamel Rater 10 test. We run an electric current through the cup to find any tiny holes that the eye cannot see.

We also have to think about the "Safety Button" again. When the button is stamped into the metal, the metal stretches thin. If the coating is not thick enough, the stretch will make the protection very weak at the center of the button. This is why you often see rust spots right in the middle of a cap. Our combination of high tin weight and flexible lacquer prevents this.

For your specific products, we can do a "Pack Test." You send us samples of your pickle juice. We put it in jars with our caps and keep them in a warm room for weeks. We watch to see which coating lasts the longest. This proves the quality before you spend any money.

Conclusion

We provide the technical safety, large inventory, and efficient formats you need to keep your production running and your food products safe.

Footnotes

1. Explains how vacuum sealing ensures food preservation and safety. ↩︎

2. Hardness scale used to measure the temper of thin steel. ↩︎

3. Property where material strength varies depending on direction. ↩︎

4. Defect causing wavy edges during metal deep drawing. ↩︎

5. Plastic polymer often replaced due to environmental concerns. ↩︎

6. Chemicals restricted in food packaging due to health risks. ↩︎

7. Metal cutting process that maximizes usage by minimizing waste. ↩︎

8. Compounds releasing vapors to prevent rust on metal surfaces. ↩︎

9. Durable coating known for chemical resistance against acidic foods. ↩︎

10. Testing device detecting microscopic discontinuities in metal coatings. ↩︎