I just heard about major delays from my current tinplate supplier. I worry about running out of material during the peak harvest season. Will your material be safe and arrive on time?

Yes, we reliably supply Electrolytic Tin Plate (ETP) with chromate passivation. This crucial treatment forms a protective film on the tinplate surface. This film ensures the tinplate resists corrosion, improves paint adhesion, and stops sulfide blackening, which is essential for safely packaging foods like meat, fish, and acidic fruits.

It is wise to look closely at every step of the supply chain. You need to know that your packaging materials are not just cheap but also top-quality and fully certified. Let’s look at the specifics of passivation and how it ensures your product’s safety and shelf life.

Is 311 Passivation Better Than 300 For Lacquer Adhesion?

I have struggled with poor lacquer adhesion before. It caused expensive batch failures. I want to know which passivation type gives the best, most reliable coating bond.

Cathodic Electrolytic Passivation (Type 311 or 314) is generally better than Chemical Passivation (Type 300) for promoting lacquer adhesion. The electrolytic process, like the common Cathodic Dichromate (CDC) treatment 1, creates a more uniform and dense chrome oxide/hydroxide film. This film offers a stable, high-energy surface that strongly bonds with organic coatings. This is vital for preventing delamination and corrosion under the lacquer.

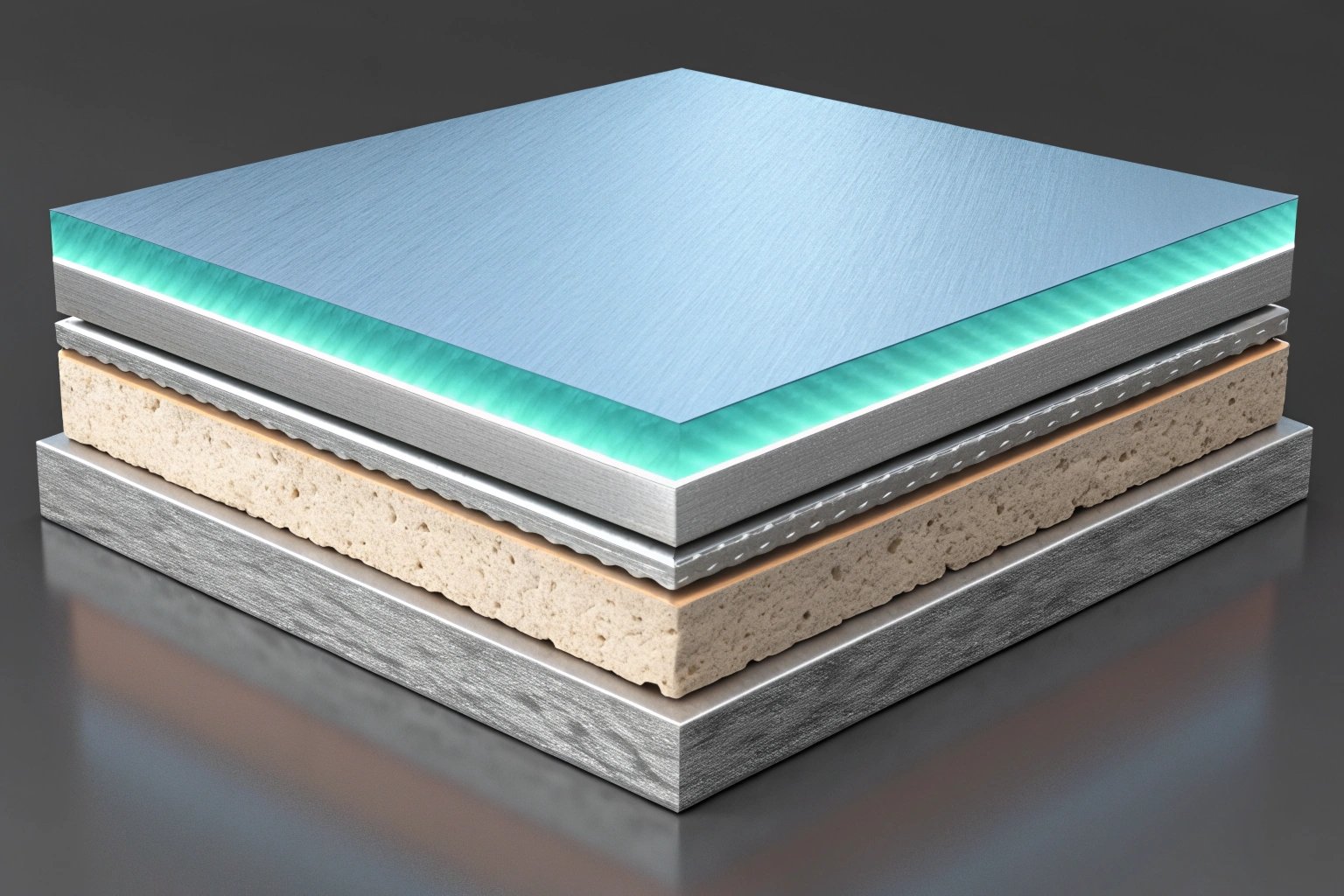

Understanding The Passivation Film Structure

The passivation film on Electrolytic Tin Plate (ETP) 2 is very thin. It is mainly made up of chromium oxides ($Cr_2O_3$) and chromium hydroxides ($Cr(OH)_3$). This combined film does two main jobs. First, it stops the tin surface from oxidizing quickly. Second, it prepares the surface so the lacquer sticks well. When we talk about Type 311 or 314, we mean Cathodic Electrolytic Passivation. We make this film by dipping the tinplate into a dichromate solution and applying an electric current. This process is very precise. It gives us excellent control over the film’s thickness and chemical makeup. The result is a more uniform, robust film.

Comparing Key Passivation Types

We mainly use two types of passivation in the industry. They are the electrolytic (Type 311/314) and the chemical (Type 300). The electrolytic method is better for food cans. It is because of the controlled environment.

| Feature | Type 300 (Chemical Dip) | Type 311/314 (Electrolytic) |

|---|---|---|

| Process | Simple chemical dipping | Electric current applied in solution |

| Film Uniformity | Less uniform; thickness varies | Highly uniform and dense |

| Primary Film | Oxide and hydroxide mixture | Mostly chromium oxides |

| Lacquer Adhesion | Good to moderate | Excellent (Industry Standard) |

| Corrosion Resistance | Moderate | Very high (best for food cans) |

Why Lacquer Adhesion Matters For Cans

Poor lacquer adhesion can cause major problems. If the lacquer does not stick well, it can lead to delamination 3. This means the protective coating peels off. Once this happens, the contents of the can touch the bare metal. For acidic foods like tomatoes or high-sulfur foods like meat, this contact is very bad. It causes rapid corrosion, leading to pinholes, leaks, or the dreaded "fat can" (swelling). Our Type 311/314 process is the most reliable way to prevent these expensive failures. It is especially important for goods that need long-term storage or high-temperature sterilization. I have heard stories from clients, like Carlos, who faced huge financial losses when a batch of canned peaches showed poor adhesion after sterilization. That is a disaster we help you avoid.

Meeting Food Safety Standards

The total chromium content in the passivation layer is an important factor. We can customize the amount based on your specific needs. Our standard total chromium content is less than or equal to $10mg/m^2$. This level is a good balance. It gives excellent performance while meeting the strict food contact safety standards. For example, it meets GB 4806.9-2016 4 in China and FDA 21 CFR 175.300 5 in the US. These standards are very important. They ensure that the packaging material is safe for food and beverages. This precision is why big companies trust our "Hua jiang" quality.

Do You Offer Trivalent Chromium Passivation (Cr3) For Eco-Friendly Markets?

I know that regulations are getting stricter globally. I need to plan ahead and secure a sustainable supply chain. Will your products meet the future’s stricter environmental rules?

Yes, we can offer Trivalent Chromium Passivation ($Cr^{3+}$) to meet the needs of eco-friendly markets and stricter global regulations. Trivalent chromium is the accepted alternative to hexavalent chromium ($Cr^{6+}$). It gives comparable performance in corrosion resistance and lacquer adhesion. It is considered safe for food contact. It allows you to enter markets with strict environmental standards, like the European Union’s REACH 6 regulations.

The Global Shift To Chromium-Free

The packaging industry is changing fast. The main driver is environmental concern. Hexavalent Chromium ($Cr^{6+}$) is a major concern 7. It is a known human carcinogen and is highly restricted. Many regions, especially the EU, are phasing it out. They are doing this through directives like REACH. We, as a large-scale manufacturer, must lead this change. We must offer solutions that are safe and sustainable. Our commitment to trivalent chromium ($Cr^{3+}$) or Chrome-Free Passivation Alternative (CFPA) shows this focus. This way, your products can easily enter any global market without regulatory risk.

Trivalent Chromium: Safety And Performance

Trivalent chromium ($Cr^{3+}$) is much safer 8 than hexavalent chromium ($Cr^{6+}$). It is essential for human nutrition in trace amounts. In our passivation process, it forms a protective layer similar to the older hexavalent process. This layer still gives the tinplate a great surface for coating.

- Safety Profile: Unlike $Cr^{6+}$, $Cr^{3+}$ is non-toxic and not classified as a Substance of Very High Concern (SVHC).

- Performance: The newest $Cr^{3+}$ systems are designed to match the performance of the old $Cr^{6+}$ systems. They offer great anti-corrosion properties and excellent bonding with the lacquer.

Comparing Old And New Passivation Systems

We are happy to work with you to choose the best passivation type. This choice depends on the specific food content and your target market.

| Passivation Type | Chromium Valence | Safety & Regulation | Ideal Application |

|---|---|---|---|

| Traditional CDC | Hexavalent ($Cr^{6+}$) | Highly regulated, being phased out | High-performance, low-cost (where permitted) |

| Trivalent Chrome | Trivalent ($Cr^{3+}$) | Safe, meets FDA/EU standards | Future-proof, all-purpose food packaging |

| CFPA | None (Zirconium/Titanium based) | Most eco-friendly, zero chrome | Specific applications in ultra-sensitive markets |

Staying Ahead Of Regulations

For a procurement director like Carlos Gomez, minimizing regulatory risk is crucial. You want a supplier who is proactive. We invest in research and development to ensure our materials meet and exceed the strictest global standards. We want to be your partner. We will help you move to the safest and most compliant packaging materials, without giving up performance or cost-effectiveness. Our massive scale and mature supply chain allow us to introduce new, compliant materials at a competitive price, which is 5% to 8% lower than our competitors. I always tell my team that compliance is not an option; it is the foundation of our B2B trade.

How Do I Test If The Passivation Film Is Stable?

I need clear, objective data to prove that your materials meet our strict internal Quality Control (QC) standards 9. How do I verify the stability of the passivation film in my lab?

You can test the passivation film stability using standard electrochemical or chemical methods. Common tests include the Tin Plate Dissolution Test (Dye Test) to check for uniform coverage and the Iron Solution Test to measure the metallic chromium content. These tests quickly show the film’s integrity and quality. This helps you confirm that the material will perform well during storage and sterilization.

Essential Quality Control Tests

A stable passivation film is the first defense against corrosion. We perform many in-house tests. We also encourage our B2B customers to verify the quality. Two of the most important tests are easy to perform in a quality control lab:

1. The Tin Plate Dissolution Test (Dye Test)

This test checks the film’s continuity and uniform coverage.

- Process: The tinplate sample is placed into a solution containing a dye and a mild acid. The acid will dissolve the tin layer where the passivation film is weak or non-existent. The dye then stains the exposed tin.

- Result Interpretation: A stable and uniform film will show very little or no staining. Large, deep-colored spots mean the passivation is poor. This is a fast way to find defects that could lead to early corrosion.

2. The Total Chromium Measurement

This test checks the chemical composition of the film.

- Process: A known area of the tinplate is dissolved into an acidic solution. Chemical analysis, usually using techniques like Atomic Absorption Spectrometry (AAS), measures the total amount of chromium that was removed from the surface.

- Result Interpretation: This number should fall within the manufacturer’s specified range (e.g., $\le 10mg/m^2$). This confirms the process was done correctly. It ensures the film is thick enough to be effective.

Testing For Lacquer Adhesion

Since the film’s main job is to help the lacquer stick, we also run coating tests. The most common is the Cross-Hatch Test. In this test, we cut a grid pattern into the lacquered surface. Then we apply and remove a piece of adhesive tape. If the lacquer does not peel away, the adhesion is good. This test is a great way to confirm the passivation film is doing its job. I remember Carlos specifically mentioned his previous supplier’s sales staff lacked the technical knowledge to explain these tests. That is why our technical experts are here to walk you through every result and spec.

Our Commitment To Consistency

Carlos Gomez cares about absolute quality consistency. This is a major pain point for him. Our large size and advanced automation help us maintain this. We have 53 Japanese Fuji coating lines 10. These lines ensure every coil we process is coated and passivated under the same precise conditions. This is the only way to eliminate batch-to-batch quality fluctuations. Our technical team is always ready to share our SGS reports and discuss our QC procedures with your technical staff. We are a manufacturer with deep technical knowledge. We can talk about "sulfide resistance" and "film integrity" with authority.

Will The Passivation Prevent Yellowing During Storage?

In the past, I had issues with my stockpiled tinplate yellowing before it was used. This led to serious visual defects in the finished cans. How does your passivation stop this from happening?

Yes, the chromate passivation treatment is specifically designed to prevent the natural oxidation and yellowing of the tinplate surface during storage. The very thin, invisible chromium oxide/hydroxide layer acts as a barrier. It slows down the reaction between the tin metal and the air. This keeps the tinplate surface bright and free from the yellow tint that forms when unprotected tin oxidizes.

The Science Of Yellowing

Tinplate is steel covered with a very thin layer of tin. Tin is a reactive metal. Over time, it will react with oxygen and moisture in the air. This forms tin oxide. Tin oxide is what causes the visible yellow or brownish discoloration 11, which we call "yellowing." This is a big problem for packaging that needs to look good, like decorative tins or can ends.

How Passivation Provides Protection

The passivation film is applied right after the tin coating. This film is the Chromium Oxide/Hydroxide layer.

- Blocking Agent: It physically separates the tin from the environment. It acts as a barrier that prevents oxygen and moisture from reaching the pure tin surface.

- Stabilizer: It is a more stable compound than tin oxide. This means it is much less likely to change or react during storage. This keeps the surface bright and ready for printing or lacquering.

Storage Conditions Still Matter

Even with the best passivation, proper storage is still critical 12. The protective film is very thin. Bad storage conditions can damage it.

| Condition | Risk to Passivation Film | Storage Best Practice |

|---|---|---|

| High Humidity | Accelerates corrosion and film breakdown | Store in a dry, low-humidity warehouse |

| High Temperature | Increases reaction speed, can cause yellowing | Keep temperature stable and cool ($\le 30^\circ C$) |

| Air Pollution | Acidic or alkaline contaminants can attack the film | Store away from chemical fumes and dust |

Ensuring Supply Stability And Quality

Our massive inventory of nearly 100,000 tons of tinplate and TFS helps solve your problem of yellowing. We can process and ship material quickly because we have so much in stock. This means the material spends less time sitting unused in a warehouse, which reduces the risk of yellowing. Our large size and stable supply chain ensure that you get freshly processed, top-quality material right when you need it, avoiding the long lead times that can cause quality issues. This means you can count on us, especially during your peak harvest season. Carlos once told me that waiting for material led to a warehouse full of spoiled tomatoes. We prevent that risk for you.

Conclusion

We confirm that we supply Electrolytic Tin Plate with stable chromate passivation, including the superior Type 311/314. This crucial step ensures strong lacquer adhesion and prevents corrosion, giving your cans maximum shelf life and safety.

Footnotes

1. Research paper on the effectiveness of Cathodic Dichromate treatment for tinplate corrosion resistance. ↩︎

2. Overview of Electrolytic Tin Plate (ETP) material, its structure, and industrial applications. ↩︎

3. Technical explanation of delamination in coated materials and its financial impact on manufacturing. ↩︎

4. The official Chinese National Food Safety Standard for metal materials and products used for food contact. ↩︎

5. US Food and Drug Administration (FDA) regulation regarding resins and polymeric coatings for food contact surfaces. ↩︎

6. Guide to the European Union’s regulation (REACH) on the Registration, Evaluation, Authorisation and Restriction of Chemicals. ↩︎

7. Environmental Protection Agency (EPA) summary and health concerns related to exposure to Hexavalent Chromium ($Cr^{6+}$). ↩︎

8. Scientific article comparing the safety profile and industrial use of Trivalent Chromium ($Cr^{3+}$) versus Hexavalent Chromium. ↩︎

9. Overview of Quality Control (QC) standards and procedures essential for material consistency in B2B supply chains. ↩︎

10. Information on our company’s manufacturing scale, including the number and type of advanced coating lines we operate. ↩︎

11. Study detailing the chemical process behind the yellow or brownish discoloration (oxidation) of tinplate during storage. ↩︎

12. Best practices and recommendations for the correct storage of tinplate to maintain quality and prevent damage. ↩︎