I often see my clients struggle to choose between gold and clear coatings for their can bottoms, wondering if the extra cost for gold actually buys better protection.

Gold lacquer and clear coatings both protect tinplate from rust, but gold offers better scratch resistance and masks sulfur staining. Clear coatings are more cost-effective and allow for easy inspection of the metal surface, making them a standard choice for high-volume food packaging.

Deciding on the right finish is not just about looks; it is about how your product survives the shipping container and looks on the retail shelf. Let me walk you through the technical differences.

Does gold exterior coating offer better rust protection than clear?

I get this question at every trade show because nobody wants to open a shipping container and find thousands of rusty can ends.

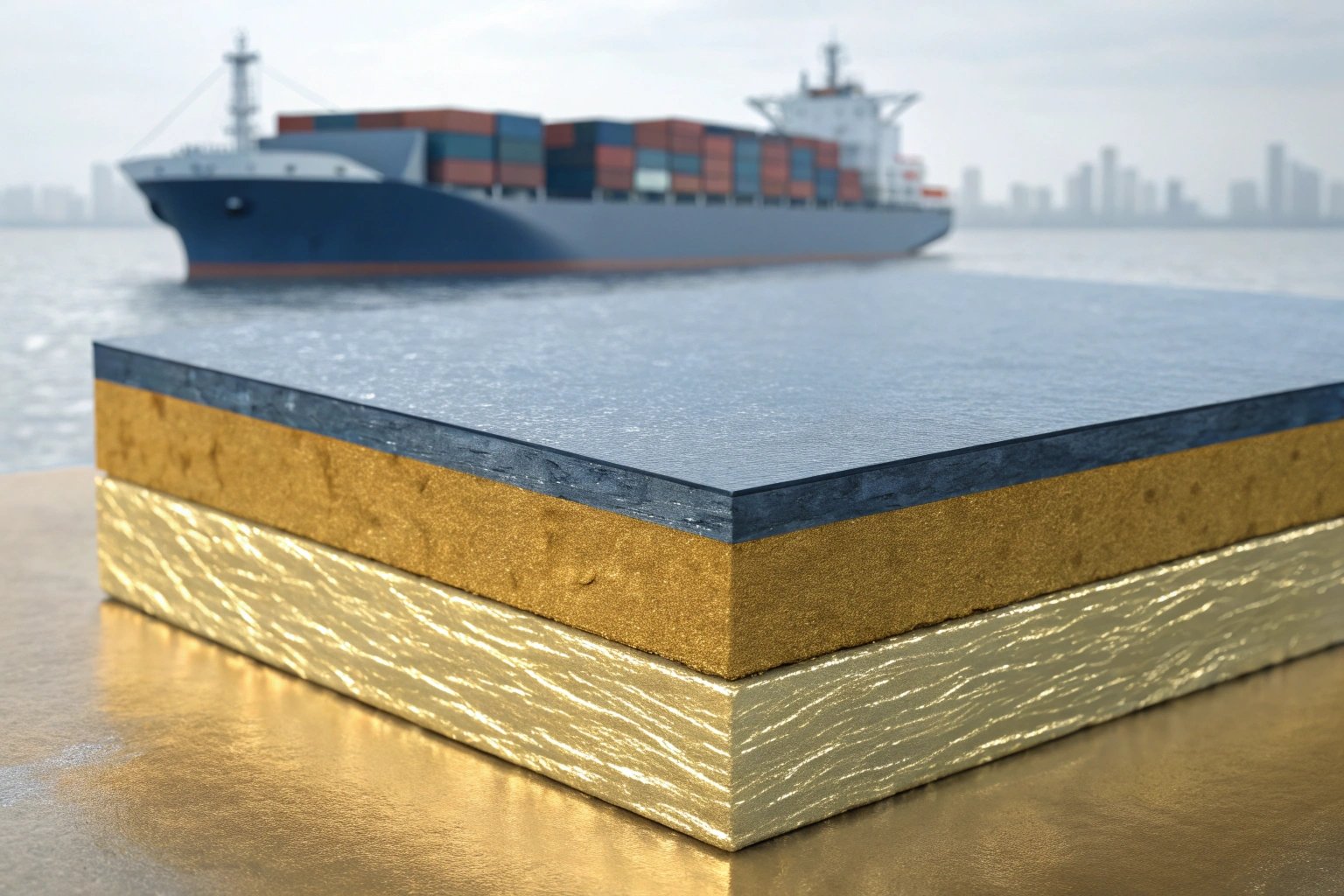

Gold coatings provide a slightly thicker physical barrier than clear lacquers, which generally results in better resistance to external oxidation and atmospheric moisture. The pigments in gold lacquer add a layer of density that helps prevent microscopic pinholes from exposing the raw steel.

The Science of Barrier Protection

When we talk about rust protection, we are really talking about how well a coating keeps oxygen and water away from the steel base. In my 27 years at Huajiang, I have seen that gold lacquer behaves differently under stress. Gold lacquer is usually an epoxy phenolic resin 1 mixed with specific pigments. These pigments do not just provide color; they add structural integrity to the film. When the metal is stamped into a bottom end, it undergoes a lot of mechanical stress. Clear coatings are thin and flexible, but gold coatings tend to be a bit tougher against the micro-cracks that happen during the forming process.

Comparing Durability in Harsh Environments

If your cans are traveling across the ocean, they face high humidity and salt air. In these conditions, the extra pigment in the gold finish acts as a shield. While clear lacquer is excellent for dry environments, gold is often the "insurance policy" for long-distance export. However, it is important to note that the chemical base of the resin matters most. Whether you choose gold or clear, if the resin is high-quality epoxy, the base protection remains solid.

Visual Inspection Advantages

One thing I tell my quality control team is that clear coatings are "honest." Because they are transparent, you can see the tinplate electrolytic process 2 results underneath. If there is a scratch or a flaw in the metal, you see it immediately. Gold lacquer can hide minor surface imperfections. For some manufacturers, this is a benefit because it keeps the product looking perfect. For others who want to verify the "tinplate grain" or surface finish, clear is the better tool.

Technical Specification Table

| Feature | Gold Lacquer | Clear Coating |

|---|---|---|

| Film Thickness | 5.0 – 8.0 g/m² | 3.0 – 5.0 g/m² |

| Rust Resistance | High | Medium-High |

| Visibility of Metal | Hidden | Fully Visible |

| Pigment Type | Gold/Yellow Toner | None (Transparent) |

How does the exterior finish impact the marketing appeal of my cans?

I have noticed that my customers in the Middle East and Southeast Asia almost always prefer gold, while my European clients often stick to clear.

The exterior finish acts as a silent salesman; gold coatings create a premium, "gift-like" feel that suggests high value and luxury. Clear coatings project a "clean" and "industrial" image, often preferred for organic or minimalist brands that want to emphasize the purity of the metal.

Cultural Preferences in Packaging

In the B2B world, we often forget that the end consumer still judges the book by its cover. A gold bottom end on a can of premium nuts or high-end coffee makes the entire package feel more expensive. It mimics the look of brass or gold, which has a universal association with quality. If you are selling into markets that value gift culture, gold is almost always the right move. I have seen sales increase just by switching from a plain silver-look bottom to a rich gold finish.

Masking the "Sulphur Black" Problem

This is a technical point that becomes a marketing point. If you are packing meat or fish, the proteins release sulfur during the heating process. This can cause sulfur staining in food cans 3, which looks like dark, ugly spots on the metal. Even though this staining is safe, it looks "spoiled" to a consumer. Gold lacquer is the perfect camouflage. The yellow tint masks the dark stains, so the can looks clean even after a long shelf life. Clear lacquer cannot hide this, which is why clear is usually reserved for fruits or dry goods that don’t have high sulfur content.

Consistency Across Product Lines

When you have a large brand with multiple products, consistency is everything. Gold lacquer is easier to "match" across different production batches. Clear coating relies heavily on the look of the raw tinplate, which can vary slightly between steel mills like Baosteel Group 4 or Shougang. If you want every can to look identical on a shelf, the pigmented gold finish provides a more uniform surface color that hides the natural variations of the steel.

Consumer Perception Table

| Market Segment | Preferred Finish | Reason |

|---|---|---|

| Gourmet/Gift | Gold | Luxury association |

| Organic/Natural | Clear | Minimalist, "pure" look |

| Industrial/Paint | Clear | Cost efficiency |

| Canned Meat/Fish | Gold | Masks sulfur staining |

Can I get custom printing on the exterior of the bottom ends?

Many of my clients ask if they can put their logo on the bottom, and the answer is a big "yes," but the coating choice changes how we do it.

Custom printing is highly effective on both finishes, but clear coatings provide the best "canvas" for 4-6 color CMYK printing. Gold coatings are typically used as a base color themselves, allowing for simple one-color brand logos or batch codes to be printed on top.

Printing on Clear vs. Gold

When we print on clear-coated tinplate at Huajiang, we are using the silver shine of the metal as our "white" background. This makes colors pop and look metallic. If you print on top of gold lacquer, the yellow tint of the gold will change your colors. For example, blue ink on a gold base will look green. If your brand has a very specific logo color, we usually recommend using a clear base or a white base rather than gold. However, if you just want a black "Best Before" date or a simple logo, gold provides a high-contrast background 5 that looks very professional.

Technical Challenges in Printing

Printing on the bottom end is harder than printing on the body of the can. The bottom end gets "curled" and stamped with heavy pressure. At our factory, we use Fuji metal printing machines 6 to ensure the ink bonds perfectly to the lacquer. If the ink doesn’t bond, it will flake off during the seaming process. Clear coatings generally have better "ink affinity," meaning the ink sticks to them more easily than the slick, pigmented surface of some gold lacquers. We always test the "adhesion" using a cross-hatch adhesion test 7 to make sure your brand name doesn’t peel off.

Customization Options for Brands

For big buyers like Carlos, I often suggest a hybrid approach. You can have a gold exterior for the premium look, but we can leave a small "clear window" for laser-coding the production date. This gives you the best of both worlds. We can also do "Matte Gold" or "Champagne Gold" if the standard bright gold is too flashy for your brand. With our 100,000-ton inventory, we can quickly pull the right material to start your custom run without waiting for steel delivery.

Printing Compatibility Table

| Printing Type | Clear Base | Gold Base |

|---|---|---|

| Full Color (CMYK) | Excellent | Poor (Colors shift) |

| Batch Coding | Good | Excellent (High contrast) |

| Brand Logos | Best for metallic effects | Best for "Prestige" look |

| Ink Adhesion | Very High | High |

Is the gold coating resistant to scratching during transport?

Nobody wants to receive a shipment of "scratched gold" ends that look like they’ve been through a war zone.

Gold lacquer is generally more resistant to visible scratching because the pigments are mixed into a hard-cured resin that acts as a sacrificial layer. While clear coatings are also tough, scratches on a transparent surface are often more noticeable because they catch the light against the shiny metal underneath.

The "Lubrication" Factor in Gold Lacquer

In our production lines, we often add a tiny amount of food-grade wax 8 or lubricant to the gold lacquer. This helps the ends slide over each other during the high-speed stamping and packing process. Because gold lacquer is a "thicker" system, it holds these additives better. This means that when the ends are stacked and vibrating in a truck or a ship, they "glide" instead of "grind." This internal lubrication is a huge advantage for global shipping.

Handling at the Filling Plant

When these ends arrive at a cannery, they go through a "feeder" or a "seamer." This machine handles the metal very quickly. If the coating is too soft, the machine will leave "track marks" on the bottom of the can. In my experience, epoxy phenolic coatings 9 are the "gold standard" for hardness. They can take the punch of a seaming machine without losing their color. Clear coatings are also very durable, but they are thinner, so if a machine is slightly out of alignment, it is more likely to cut through a clear coat than a gold one.

Cost vs. Risk Management

I always tell my customers to weigh the 8-15% extra cost of gold against the risk of rejection. If your customer is a global supermarket chain 10 with strict quality standards, one scratched can bottom can lead to a rejected pallet. Gold lacquer provides that extra cushion of safety. It’s not just a color; it’s a structural layer. For high-volume producers, the "yield" of perfect cans is often higher when using gold because it hides the minor scuffs of the industrial world.

Conclusion

Choosing between gold and clear comes down to your budget and your market. Gold offers better protection and a premium look, while clear is efficient and clean.

Footnotes

1. Explanation of epoxy phenolic resin properties used in metal packaging coatings. ↩︎

2. Technical overview of the electrolytic tinning process for steel substrates. ↩︎

3. Research on the causes and prevention of sulfur staining in canned food. ↩︎

4. Official site of Baosteel, a major global supplier of high-quality tinplate. ↩︎

5. Principles of color contrast and visibility for product packaging design. ↩︎

6. Information on advanced metal printing technology and Fuji coating lines. ↩︎

7. Industry standard for testing the adhesion of coatings on metal surfaces. ↩︎

8. Regulatory guidelines for food-grade waxes and lubricants in food contact materials. ↩︎

9. Specialized industrial coatings for metal containers and food packaging durability. ↩︎

10. Insight into quality control standards for global retail and supermarket chains. ↩︎