I know how frustrating it is when a batch of printed cans gets rejected because of microscopic dust. It destroys your production efficiency, hurts your profit margins, and risks your reputation with food brands.

We prevent tin dust by optimizing anode current density to reduce sludge, using high-suction vacuums on cutting lines, and applying precise electrostatic oiling. These steps ensure a pristine surface for lacquering and printing, meeting the strict food safety standards you require for your cannery.

Let’s break down exactly how we eliminate these particles from the source to the final shipment, so you can run your lines with confidence.

Do you clean the sheets before lacquering to remove dust?

You should not have to clean sheets yourself; the steel mill must deliver them ready for your coating lines immediately to save you time and money.

Yes, we employ rigorous cleaning protocols. We use inline magnetic separators and high-pressure air knives before the lacquering stage. This removes ferrous dust and loose tin particles, ensuring excellent adhesion for your food-grade coatings without additional prep work.

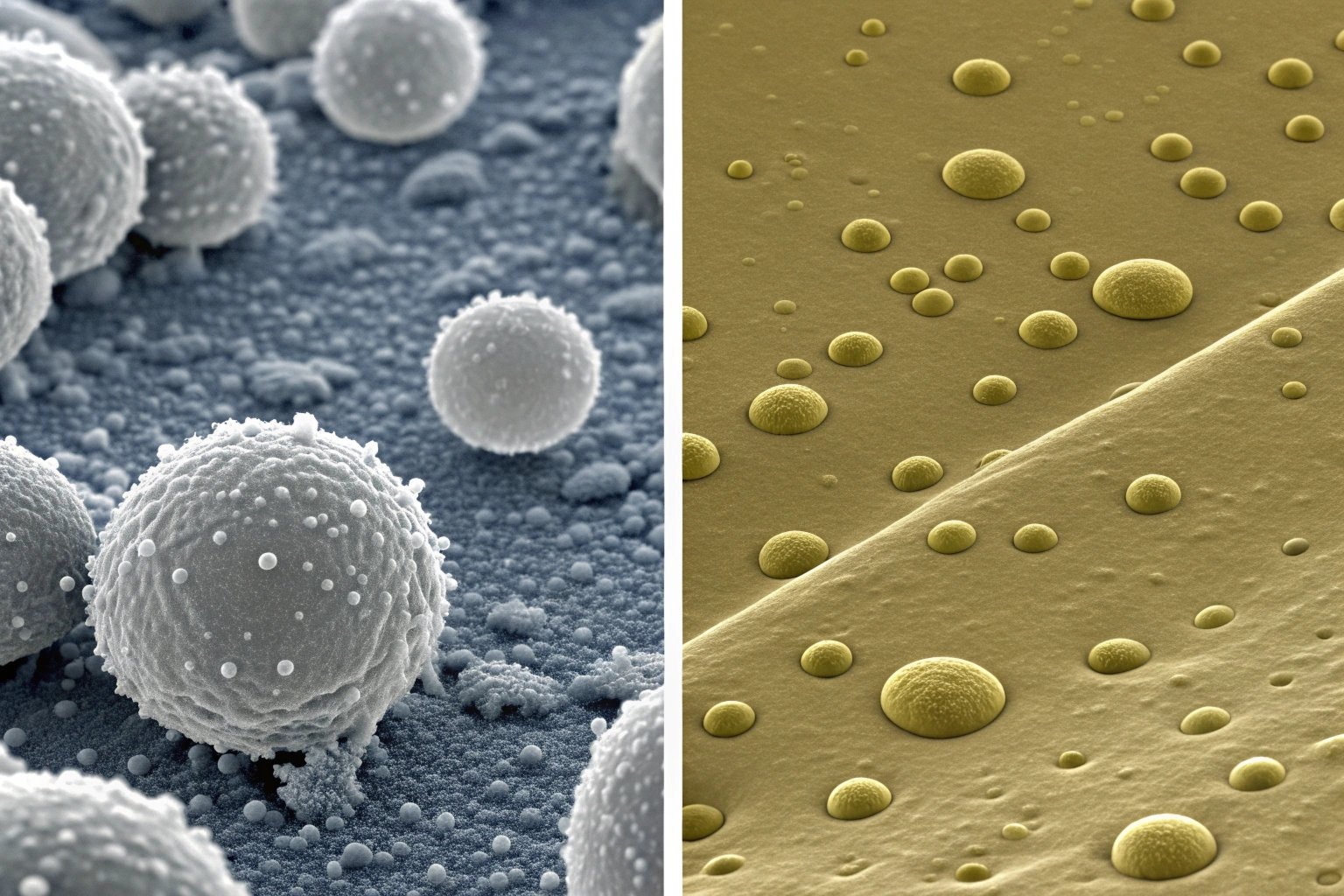

To ensure the material I send you is perfectly clean, we have to look at where the dirt comes from. In the tinplate industry, "dust" is usually a mix of iron fines from the steel base and tin oxides 1 from the plating process. If we do not control this at the source, no amount of cleaning later will be enough.

Source Control: Managing the Chemistry

The biggest enemy of a clean surface is "anode sludge." In our electrolytic plating baths, we use tin anodes to coat the steel. Ideally, the tin dissolves into the liquid and sticks to the steel. However, if the chemical balance is wrong, the tin turns into a useless sludge (Stannic Oxide) instead. This sludge floats in the bath and can settle on your steel sheet like fine dust.

I ensure my factory controls this by using strict monitoring of the anode current density 2. We also add specific antioxidants to the bath. These chemicals stop the good tin from turning into bad sludge. By keeping the plating bath clean, the strip that comes out is naturally cleaner. It is like cooking with clean water; the food tastes better.

Process Interception: The Cleaning Line

Even with clean chemistry, some dust is inevitable during the high-speed movement of the steel coil. This is why our cleaning process is aggressive. Before the steel even reaches the lacquering stage, it goes through a specialized cleaning section.

- Magnetic Separation: We pass the sheet near strong magnets. These pull away any iron dust that might have come from the edges of the steel.

- Air Knives: We use high-velocity air knives 3—imagine a very powerful, precise leaf blower—that blast across the surface. This blows away non-magnetic particles like cardboard dust or loose tin oxides.

- Vacuum Recovery: We don’t just blow the dust into the air; we vacuum it up immediately so it doesn’t settle back down.

Here is a comparison of what happens when you buy from a standard mill versus a mill with advanced cleaning protocols like Huajiang:

| Feature | Standard Mill Process | Huajiang’s Process | Benefit to You |

|---|---|---|---|

| Sludge Control | Basic filtration | Antioxidants + Density Control | Less initial dust on the coil |

| Debris Removal | Compressed air blow-off | High-pressure Air Knives | Removes 99% of loose particles |

| Environment | Open workshop | Positive pressure zones | Prevents airborne dust re-settling |

| Result | requires wiping before print | Ready to print immediately | Saves labor and solvent costs |

By handling this "process interception" internally, I make sure that when you open a package of our tinplate in Mexico or Spain, it is ready for your machines immediately.

Will tin dust cause rough spots on my printed cans?

Seeing rough spots or "starry nights" on your finished cans is a nightmare that hurts your brand reputation and causes expensive claims from your clients.

Absolutely, tin dust is a primary cause of printing defects. Loose particles create uneven surfaces, leading to "fisheyes" in the lacquer and rough textures in the ink. This compromises both the aesthetic appeal and the corrosion resistance of the can.

When you are printing on metal, the surface must be smoother than paper. Any particle that sits between the metal and the ink acts like a tiny stone in a shoe—it causes big problems. I want to explain exactly why this happens so you can identify if your current defects are caused by dust.

The "Fisheye" Effect

When you apply a coating (lacquer) to the tinplate, the liquid wants to spread out evenly. If there is a speck of tin dust, the lacquer pulls away from it. This creates a small crater that looks like the eye of a fish, known as fisheyes 4.

- Aesthetics: Your customer’s logo looks broken or dirty.

- Safety: The center of that "fisheye" has no coating. If you pack acidic food like tomatoes or pineapple, the acid will attack that bare spot. This leads to rust and swollen cans 5.

Critical Defects caused by Dust

Beyond just looks, dust ruins the physical integrity of the can. If you have "rough spots," it means the ink is sitting on top of the dust, not on the metal. During the can-making process, your machines will bend and shape the metal. The dust will break off, taking the ink with it. This leaves you with a scratched, ugly can that no supermarket wants to buy.

I have seen many factories in Europe struggle with this. They think their oven temperature is wrong, or their ink is bad. But 90% of the time, it is simply dust on the raw material.

Impact on Tooling

Dust is abrasive. Stannic Oxide 6 particles are harder than pure tin. If your sheets are dusty, that dust builds up on your expensive blankets and rollers.

- It forces you to stop the line and clean the blankets more often.

- It wears out your printing plates faster.

Here is a breakdown of how dust impacts your specific production steps:

| Defect Name | Appearance | Consequence for Canner |

|---|---|---|

| Fisheye / Cratering | Small circular voids in lacquer | Exposed metal, high rust risk |

| Pimple / Inclusion | Small bump under the ink | Ink flaking off during forming |

| Hickeys | Halo-like spots in solid colors | Visual rejection by brand owners |

| Scumming | Ink appearing in non-image areas | Dirty appearance, line stoppage |

By ensuring our tinplate is free of these particles, I help you avoid these "B-grade" quality issues. Your production line stays running, and your customers remain happy.

How do I maintain my decoiler to avoid generating dust?

Even the best material can get ruined if your own equipment accidentally generates dust during the uncoiling process at your factory.

Maintaining your decoiler involves regular cleaning of rollers and checking tension settings. Excessive tension causes slippage that grinds the soft tin surface, creating fresh dust. We recommend using rubber-lined rollers and keeping the area free of static electricity.

Sometimes, I ship perfectly clean coils to a customer, but they still complain about dust. When we investigate, we often find the dust is being created inside their factory. Tin is a very soft metal. If you handle it too roughly, it will shed particles. I want to share some technical advice on how to stop this from happening on your end.

Controlling Strip Tension

The most common cause of self-generated dust is "micro-slippage." This happens at the decoiler (uncoiler). If the tension on the strip is too high, or if the rollers are not spinning at the exact same speed as the strip, the metal drags across the roller surface.

- This friction acts like sandpaper.

- It grinds tiny particles of tin off the sheet.

- These particles stick to the roller, then get pressed back into the next section of the sheet.

You must adjust your braking tension. It should be just enough to keep the coil tight, but not so tight that the feed rollers slip.

Roller Maintenance Best Practices

Check your rollers today. Are they made of steel? Steel rollers on tinplate are a bad combination for dust.

- Use Rubber or Polyurethane: We recommend covering your drive rollers with a soft material. This grips the sheet better without scratching it.

- Clean the Build-up: Even with rubber rollers, tin picks up. You need to wipe these rollers daily with a solvent. If you see grey or black lines on your rollers, that is tin dust waiting to ruin your next batch.

Managing Static Electricity

When you uncoil metal quickly, you create static electricity 7. Static is a magnet for dust. It pulls dust from the air and sticks it to your sheet.

- Install "static eliminators" or ionization bars right after the uncoiler.

- Ensure your machine is properly grounded.

| Maintenance Check | Frequency | Why it matters |

|---|---|---|

| Wipe Feed Rollers | Every Shift | Removes accumulated tin fines |

| Check Tension | Every Coil Change | Prevents slippage and grinding |

| Inspect Roller Surface | Weekly | Damaged rollers scratch the tin |

| Vacuum Area | Daily | Keeps the environment clean |

| Install Ionizers | Once | static eliminators 8 neutralize charge |

By following these simple steps, you ensure that the high-quality surface I send you stays perfect until it becomes a can.

Is your cutting line equipped with dust vacuum systems?

You need assurance that the cutting process, which naturally creates debris, is fully contained within our factory so it doesn’t end up in your container.

Yes, all our cutting lines utilize advanced vacuum extraction systems. We place suction units directly at the shear blade interface to capture microscopic tin fines immediately upon creation. This prevents dust from settling back onto the sheet surface before packaging.

Cutting a large coil into smaller sheets is a violent process. A metal blade shears through steel at high speed. This action always creates microscopic debris. If a supplier tells you their cutting process creates "zero dust," they are lying. The difference lies in how we manage that dust.

The Importance of Blade Sharpness

First, we focus on the knife itself. A dull knife tears the metal instead of slicing it. Tearing creates jagged edges and lots of dust.

- At Huajiang, we have a strict schedule for grinding our shear blades.

- We use high-grade carbide blades 9 that stay sharp longer.

- A clean cut means less debris is generated in the first place.

Our Vacuum Extraction Technology

We do not just let the dust fall. We install powerful vacuum hoods right next to the cutting head.

- Localized Suction: The vacuum is not on the ceiling; it is millimeters away from the cut. It captures the particles the millisecond they are born.

- Negative Pressure: We create a negative pressure zone around the cutter. This means air flows into the vacuum, not out into the room.

Terminal Governance: Packaging

Once the sheet is cut and cleaned, we must protect it. We do not leave stacks of tinplate sitting open in the warehouse.

- We wrap the stack immediately.

- We use Volatile Corrosion Inhibitor 10 (VCI) paper. This paper not only stops rust but also acts as a barrier against dust in the air.

- We place a hard cover on top (a "waster sheet") to protect the good sheets during transport.

Why Inventory Matters

I mentioned earlier that we hold 100,000 tons of coil stock. This allows us to cut material fresh for your order. We don’t sell you old sheets that have been gathering dust in a corner for six months. We take a fresh coil, cut it on our vacuum-equipped line, wrap it, and ship it to you.

| Feature | Benefit |

|---|---|

| Carbide Shear Blades | Ensures a clean slice with minimal fracturing |

| Point-of-Source Vacuum | Sucks up dust before it can land on the sheet |

| Immediate Wrapping | Seals the cleanliness inside the package |

| Fresh Cutting | Prevents long-term storage dust accumulation |

This comprehensive system is how we guarantee that when you inspect our material in your factory, it meets the high standards required for FDA-compliant food packaging.

Conclusion

We control dust through chemical precision, advanced cleaning lines, and vacuum-equipped cutting. This rigorous discipline guarantees your canning lines run smoothly without quality interruptions or safety risks.

Footnotes

1. Chemical overview of stannic oxide formation in plating. ↩︎

2. Technical insights on optimizing current density for plating. ↩︎

3. Explanation of how air knives remove surface debris. ↩︎

4. Guide to identifying and preventing fisheye coating defects. ↩︎

5. Safety risks and causes of swollen metal cans. ↩︎

6. Scientific properties and hardness of Tin(IV) oxide. ↩︎

7. OSHA guide on hazards of static electricity accumulation. ↩︎

8. How static eliminators work to neutralize surface charge. ↩︎

9. Durability benefits of cemented carbide in cutting tools. ↩︎

10. Overview of VCI technology for corrosion protection. ↩︎