I know how stressful it is when your production line stops because of a tiny leak. I have spent years helping food packers avoid these costly disasters.

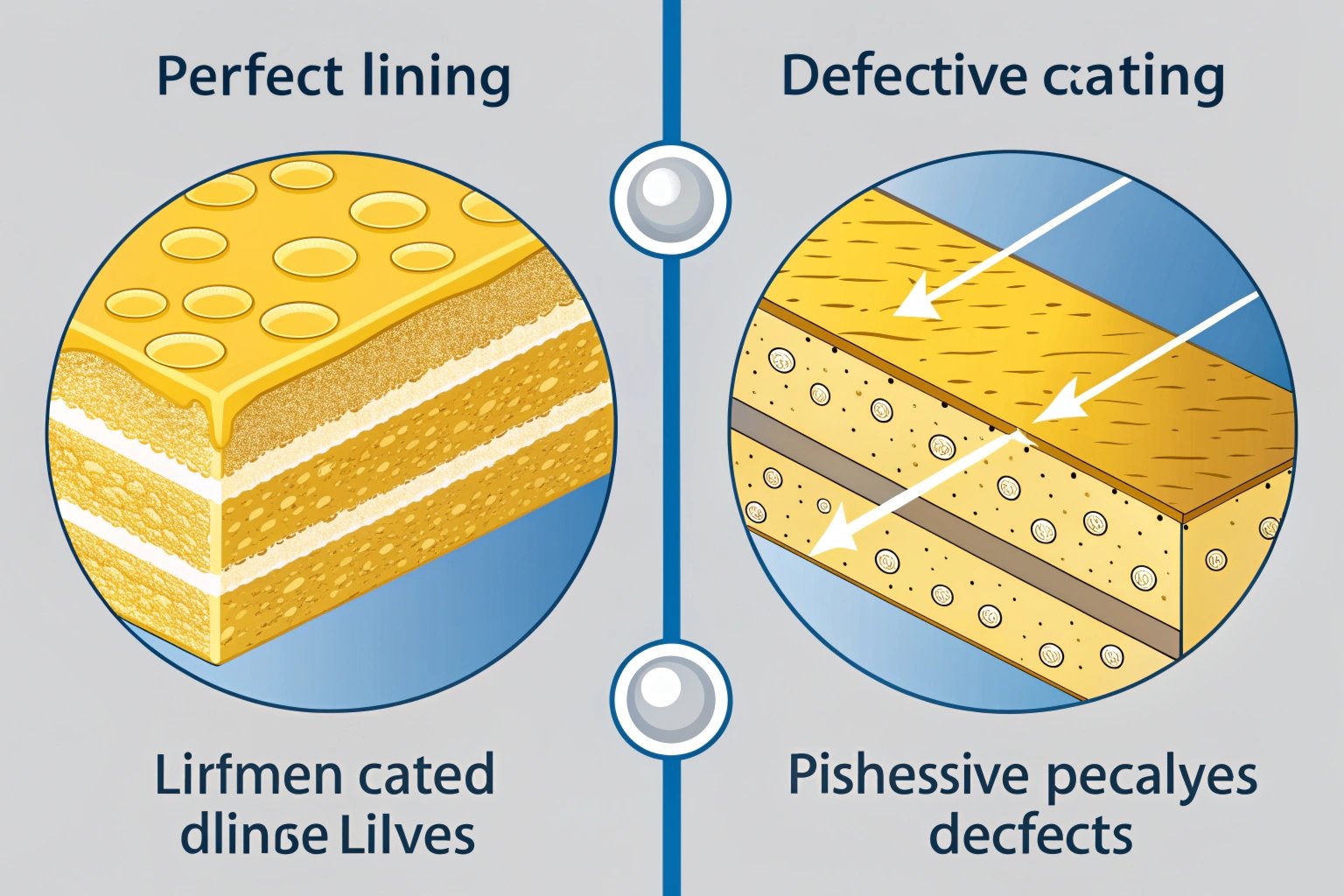

Checking lining consistency requires a mix of visual inspection, enamel rating tests, and precise film weight measurements. By verifying the uniform thickness and coverage of the lacquer, you ensure that no bare metal touches your food product, preventing rust and leaks.

You do not want to find out about a lining failure after 10,000 cans are already in the warehouse. Let me show you exactly how we guarantee consistency at Huajiang.

How can I visually inspect the lining for gaps or bubbles?

I always tell my team that your eyes are the first line of defense. If you cannot see the problem, you cannot fix it before it ruins a batch.

Visual inspection involves using diffuse lighting 1 to scan the tinplate end for pinholes, bubbles, or uneven color. You must rotate the end 360 degrees to check that the lining compound covers the entire curl and score area perfectly.

The Importance of Proper Lighting

When I walk through our factory in Fujian, I look at the inspection stations first. You need bright, white light that does not create a harsh glare. If the light is too direct, you will miss small bubbles or "fisheyes" in the lacquer. These tiny holes happen when dust or oil gets on the metal before coating.

We look for "skips," which are areas where the metal shows through. In a high-speed line, a spray nozzle might clog for a fraction of a second. That tiny skip is where corrosion starts. I check the "bead" (the thick part of the lining) to make any sure it is a smooth, continuous circle. If the bead looks wavy or has gaps, the seal will fail when you seam the can 2.

Common Visual Defects Table

| Defect Name | What it looks like | Primary Cause | Risk Level |

|---|---|---|---|

| Pinholes | Tiny black or silver dots | Dust or air bubbles | High (Leads to rust) |

| Blushing | Cloudy or white patches | Poor curing or moisture | Medium (Adhesion issues) |

| Craters | Small "volcano" shapes | Oil contamination | High (Bare metal exposure) |

| Scratches | Straight lines in coating | Mechanical handling | Medium (Potential rust) |

Checking the "Score" Area

If you are using Easy Open Ends 3 (EOE), the "score" line is the most dangerous spot. This is where the metal is thinned so you can pull the tab. I use a magnifying glass to check if the lacquer has cracked along this line. If the lining is too brittle, it will snap during the stamping process. We make sure our coating is flexible enough to stretch without breaking. This is why we use 53 Japanese Fuji coating lines; they give us the precision that cheaper machines simply cannot match.

What tools do I need to measure the volume of the lining compound?

I believe that what you cannot measure, you cannot control. You need more than just a good eye; you need hard numbers to prove your quality.

To measure lining volume accurately, you need an enamel rater 4, a magnetic induction thickness gauge, and a precision scale for gravimetric testing. These tools tell you exactly how many grams of lining are protecting your food products.

Using the Enamel Rater

The enamel rater is my favorite tool for peace of mind. We take a finished end and put it in a special salt solution. Then, we pass a small electric current through it. If the lining is perfect, no electricity should flow because the lacquer acts as an insulator. If the machine shows a high reading (in milliamps), it means there is exposed metal.

Coating Weight Standards Table

| Product Type | Recommended Film Weight (g/m²) | Acceptable mA Range | Test Frequency |

|---|---|---|---|

| General Food | 5.0 – 8.0 | < 0.5 mA | Every 2 hours |

| Acidic Fruits | 8.0 – 12.0 | < 0.1 mA | Every 1 hour |

| High-Sulfur Meat | 10.0 – 15.0 | < 0.1 mA | Every 1 hour |

Gravimetric (Weight) Testing

This is the "old school" but most reliable way. I take a piece of tinplate 5, weigh it, strip the lining off with a chemical, and weigh it again. The difference tells me the exact weight of the dry film. At Huajiang, we keep a huge stock of over 100,000 tons of tinplate from top mills like Baosteel 6. Because our raw material is so consistent, our weight tests stay very stable. We aim for a deviation of no more than $\pm 1.5g/m^2$.

Magnetic Induction Gauges

For a quick check without destroying the sample, we use handheld digital gauges 7. These use magnets to "feel" how far the metal is from the sensor. It gives us an instant thickness reading. I make sure my QC team checks at least five spots: the center, the edges, and near the curl. If one side is thicker than the other, I know our application rollers need adjustment. This prevents "lopsided" lining which is a common cause of sealing failure.

Why does uneven lining lead to micro-leaks in my finished cans?

I have seen many customers lose money because they tried to save a few cents on cheap ends. Uneven lining is a "silent killer" for your brand reputation.

Uneven lining creates weak spots where the metal is too thin to resist the acids in food. During the seaming process 8, a thin lining can crack, allowing bacteria to enter or product to leak out through microscopic holes.

The Science of Corrosion

Think of the lining as a shield. If the shield has a thin spot, that is where the enemy (acid or salt) will strike. In high-acid foods like tomatoes or pineapple, the liquid will eat through a thin spot in weeks. This creates "hydrogen swells" or "fat cans." I have helped clients move away from suppliers who had "thin spots" because they didn’t maintain their machines.

Why Seams Fail

When you seam the bottom end onto the can body, the metal is bent and squeezed under high pressure. If the lining compound is not thick and even, it will not fill the gaps in the seam. This leads to "micro-leaks." You might not see liquid leaking out, but air and bacteria can get in.

Sealing Performance Comparison

| Feature | Uniform Lining (Huajiang) | Inconsistent Lining (Cheap Source) |

|---|---|---|

| Seam Tightness | 100% gap filling | Air pockets in seam |

| Corrosion Resistance | 2+ years shelf life | Early rust (6-12 months) |

| Bacteria Barrier | Hermetic seal | Risk of spoilage |

| Production Speed | High (stable performance) | Frequent jams/stoppages |

Adhesion and Flexibility

It is not just about thickness; it is about how well the lining sticks to the tinplate. We use a cross-hatch test 9 where we cut a grid into the coating and try to pull it off with tape. If any squares come off, the batch is rejected. We also perform "retort tests." We put the ends in a pressure cooker at 121°C for 30 minutes. If the lining bubbles or changes color, it is not good enough for our customers.

What is the acceptable rejection rate for lining defects?

I know you have a business to run, and you need to know what "normal" looks like. No factory is perfect, but the best ones come very close.

In a professional B2B environment, the acceptable rejection rate for lining defects should be less than 0.5%. Leading manufacturers like Huajiang aim for even lower rates by using automated vision systems 10 to catch errors instantly.

Setting Your Quality Limits

When I talk to procurement directors like Carlos, they want to know they won’t get a "bad batch." I recommend a sampling plan where you check 10% of every lot. If you find more than 1 or 2 defects in 1,000 ends, you should stop and investigate. Our automated cameras check every single one of the 6 billion ends we make each year. If a camera sees a skip, a bubble, or a scratch, that end is blown off the line by air pressure instantly.

Why 0.5% is the Magic Number

In the canning world, one bad end can ruin a whole case of food. If you have a 1% defect rate, and you pack 1 million cans, you have 10,000 potential failures. That is a nightmare for any supply chain manager. By keeping our costs 5-8% lower through automation rather than cutting corners on quality, we give you a better product for a better price.

Handling Rejections

I always tell my clients: "Judge a supplier by how they handle a mistake." If we ever send a batch that does not meet the mA spec or the visual standard, we take responsibility. We have a clear claim mechanism. Because we track every coil of tinplate back to the mill, we can find out exactly what went wrong. Most low-cost traders will just stop answering your emails. We stay with you because we want to be your partner for the next 20 years, not just one sale.

Conclusion

Checking lining consistency is the only way to guarantee a safe, long-lasting can. By using the right tools and strict standards, you can avoid costly recalls and keep your customers happy.

Footnotes

1. Understand how diffuse lighting reduces glare during industrial surface inspections. ↩︎

2. Comprehensive guide to the double seaming process for airtight metal packaging. ↩︎

3. Technical overview of manufacturing technology used for easy open can ends. ↩︎

4. Standard procedures for using enamel raters to detect metal exposure in coatings. ↩︎

5. Detailed specifications and properties of tinplate used in the food industry. ↩︎

6. Catalog of high-quality tinplate products from the global manufacturer Baosteel. ↩︎

7. How magnetic induction gauges measure non-magnetic coating thickness on ferrous metals. ↩︎

8. Identifying and preventing common defects during the can seaming process. ↩︎

9. Official ASTM method for evaluating coating adhesion through cross-hatch testing. ↩︎

10. Benefits of implementing machine vision for high-speed automated quality control. ↩︎