Have you ever worried about can leaks or weak seams that could ruin your whole batch? I know that pain, and it’s a major risk for our customers.

Yes, our Electrolytic Tin Plate (ETP) is absolutely suitable for welding three-piece food cans; it is the industry standard material designed for electric resistance side-seam welding. The tin coating on our material ensures excellent weldability and is optimized for the high-speed production lines common in major can-making facilities.

Keep reading. You need to know exactly how our material is designed to give you the strong, reliable, and food-safe seams your canning operations demand, without any unexpected failures.

How Do I Adjust My Welder Current for Your Specific Steel Grade?

Dealing with different steel suppliers means constantly tweaking your Soudronic welder settings, which costs time and money. I understand the frustration.

You should adjust the welder current based on the specific thickness, temper, and tin coating weight of the ETP we supply, always aiming for the optimal welding window defined by the steel’s base composition. Our ETP uses a controlled low-carbon steel base and precise plating, allowing for more stable current settings compared to material with inconsistent properties.

Weldability is All About Consistency

The real secret to high-speed welding is not just a high current, but consistent material properties 1. When I talk to engineers like Carlos Gomez, their main fear is batch variation that forces constant machine stops and adjustments. This is why we focus on two core material design factors: base steel and tin coating.

The Base Steel Composition Matters

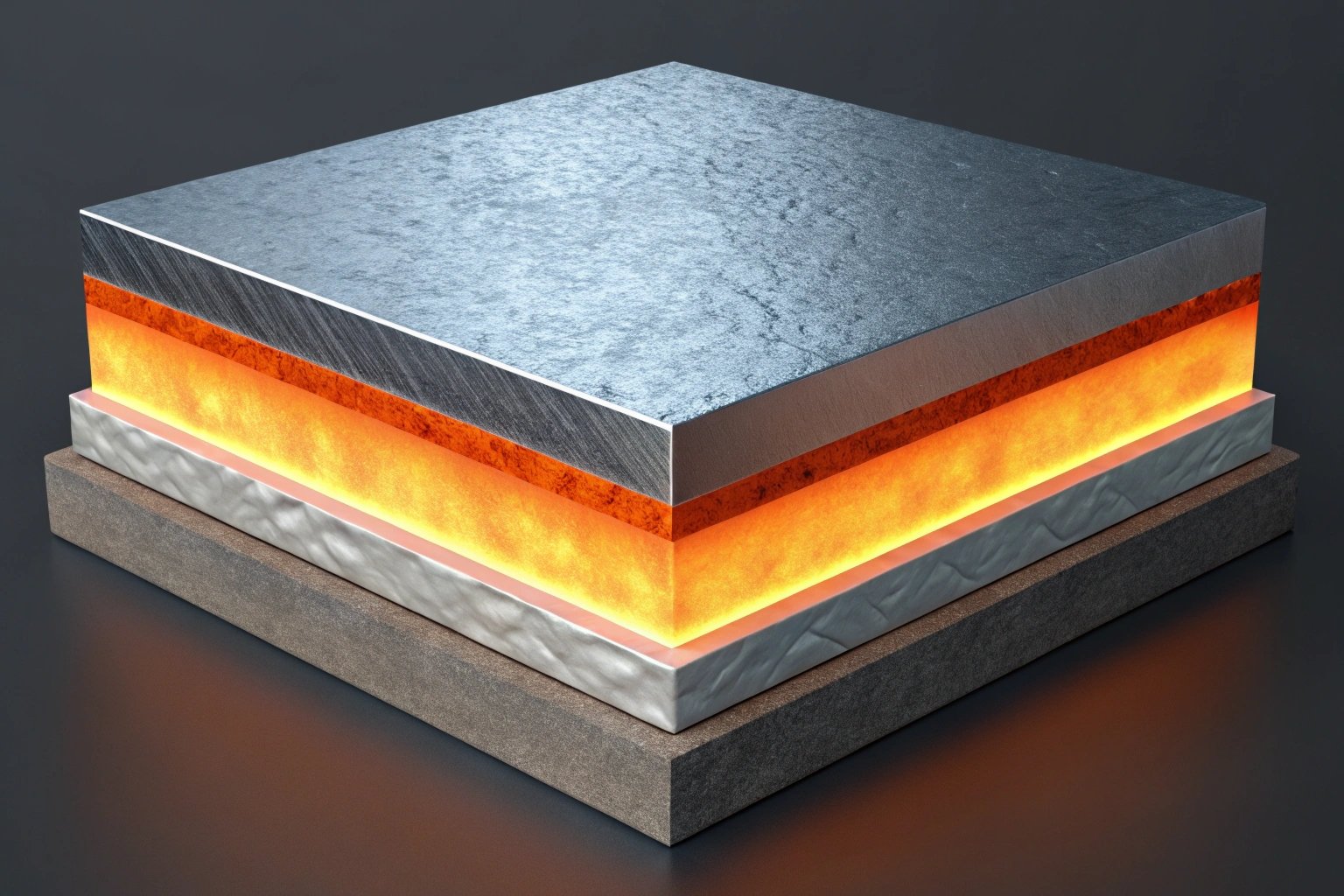

The electrical resistance welding process uses heat generated by passing a high current through the overlapped metal sheets. If the base steel, the Black Plate, has too much carbon or other impurities, it changes the resistance.

- Low Carbon Content: We specifically use low carbon cold-rolled base materials 2, such as LCAK or DR-8 grade. The carbon content is strictly kept below $0.003\%$. This low-carbon level is critical. It helps to reduce the risk of the weld becoming brittle. A brittle weld can crack later during the flanging or seaming process, or even during high-temperature sterilization (retorting).

- Controlling Impurities: We strictly manage elements like Manganese (Mn) and Phosphorus (P) 3. High levels of these elements can also negatively affect the steel’s weld behavior and mechanical strength. By controlling these, we ensure the final seam has the high toughness and tensile strength needed to withstand pressure.

The Role of Tin in Welding

The tin layer acts like a lubricant and a conductive layer during the resistance welding process.

| Tin Coating Weight (g/m²) | Typical Application | Weld Current Requirement | Notes |

|---|---|---|---|

| 2.8 / 2.8 (D2.8) | General Food Cans | Moderate | Most common, good balance of corrosion resistance and weldability. |

| 5.6 / 5.6 (D5.6) | Highly Corrosive Food | High | Requires higher current to burn off more tin; slower welding speed. |

| 1.1 / 2.8 (10/25) | Differential Coating | Lower / Optimized | Outer (welding) side is thinner, improving welding stability. |

The key is the thickness of the tin coating 4. If the tin layer is too thick, you need more current to "burn off" the excess tin and make a proper steel-to-steel weld. The excess tin can also splatter and foul the copper electrode wheels. Our standard $2.8 / 2.8 \text{ g/m}^2$ (D2.8) or differentially coated ETP is engineered to minimize this issue. We control the thickness deviation to less than $\pm 1\mu\text{m}$. This extreme consistency means your welding machine needs fewer current adjustments, which improves your line’s uptime and efficiency. It is important to match the tin layer with your machine’s settings.

Do You Leave a Plain Margin (Unprinted Edge) for the Weld Seam?

When my customers get pre-printed sheets and the weld area is covered, they have to stop the line to clean it up, which is a major headache. We always try to prevent that.

Yes, we must leave a clean, unprinted, and unlacquered margin on the can body blank for the side-seam weld area, as the welding process requires direct metal-to-metal contact to form a strong joint. This bare metal strip, typically about 6 mm wide, ensures optimal electrical conductivity and a reliable, defect-free resistance weld.

Why the Plain Margin is Non-Negotiable

In three-piece can manufacturing 5, the can body is formed by rolling a flat rectangular blank into a cylinder. The two edges of the blank are then overlapped slightly and resistance welded to form the side seam. For this welding to work correctly, the electrical current needs a clean path.

Lacquer and Print Must Be Avoided

Applying lacquer or printing ink 6 to the weld margin would create an electrical insulator.

- Insulation Failure: If the margin has lacquer, the high-frequency current cannot flow correctly. This leads to arcing, excessive heat, weak welds, and potential damage to the welding wheels. The result is a ‘cold weld’ or ‘hot weld’ that fails the pressure or leak test.

- The "Side Stripe" Process: The internal lacquer, which protects the food from the metal, is applied after welding. The welding process itself burns off the tin along the weld line. Therefore, a secondary operation—the side-stripe application 7—is always needed to coat the exposed steel inside the can. Our job is to deliver the sheets so they are ready for the initial welding step.

Huajiang’s Precision in Pre-Press

Since we offer OEM printing services and have five modern coating and printing factories, we use highly precise alignment systems to ensure the margin is perfect.

| Product Type | Margin Requirement | Width of Bare Margin | Role in Welding |

|---|---|---|---|

| Printed Can Bodies | Must be bare ETP | Typically 6 mm – 7 mm | Provides electrical contact for resistance welding. |

| Coated Ends/Lids | No weld margin needed | Full surface coated | These parts (bottom and top lids) are mechanically seamed, not welded. |

| TFS Sheets | Not weldable | N/A | TFS uses a cement-seam or must be used for drawn cans. |

Our coating lines, equipped with 53 Japanese Fuji coating lines, ensure that the coating and printing are precisely registered. This prevents any ‘slop’ where the lacquer accidentally creeps into the essential bare margin. This precision in the pre-press stage is a major benefit for our clients, reducing their internal scrap rate.

Does the Free Tin Layer Affect the Welding Speed?

Many engineers believe the free tin layer slows them down because they think they need to burn it all off. Is that true for our product?

Yes, the thickness of the free tin layer directly affects the minimum current needed and thus the maximum possible welding speed, but our precisely controlled plating minimizes any negative impact. A heavier tin coating requires more energy to melt and expel from the joint area, which forces a reduction in line speed to achieve a high-quality, continuous weld nugget.

Precision Plating for Peak Performance

The "free tin" layer is the outermost, pure-tin layer on the ETP surface. It gives ETP its excellent corrosion resistance and solderability. However, in resistance welding 8, the goal is to form a weld between the two layers of steel, not the tin. The tin needs to be pushed out of the way.

The Welding Process and Tin Expulsion

- Contact: The electrode wheels press the two sheets together at the weld margin.

- Current Flow: High-frequency current is passed through the overlap.

- Heating: The electrical resistance heats the material, primarily at the interface of the two steel sheets.

- Expulsion: The tin layer, which has a low melting point ($232^\circ\text{C}$), melts and is expelled or pushed away from the direct contact zone by the pressure of the electrode wheels.

- Steel Fusion: Once the tin is removed, the steel surfaces come into contact, and the heat forms a true metallic bond, the weld nugget.

If the tin layer is too thick (e.g., $5.6 \text{ g/m}^2$), the welder must supply more energy and maintain pressure longer to fully expel the tin. This forces the welding machine to run slower. Our commitment to tight control over the $\pm 1\mu\text{m}$ thickness variation means that the energy required for expulsion is extremely consistent.

- Optimizing the Coating: For high-speed lines, we often recommend our differentially coated ETP. For example, a $1.1 / 2.8 \text{ g/m}^2$ (or 10/25) grade where the $1.1 \text{ g/m}^2$ side is the exterior welding surface. This thinner outer layer allows for a much cleaner and faster weld because there is less tin to expel. This can significantly boost the customer’s production rate without compromising the corrosion resistance provided by the heavier interior coating.

- Weld Strength Metrics: After welding, we expect the weld seam to achieve a high tensile strength 9. Our material is designed to hit an ultimate tensile strength of $\ge 290 \text{ MPa}$. This is the technical proof that the tin was successfully managed and the steel-to-steel bond is sound. This weld strength is what allows the can to pass the final leak test after the $121^\circ\text{C} / 30 \text{ min}$ high-temperature sterilization process.

Can I Use Your Material for High-Speed Soudronic Welders?

You are running a major operation and you need material that works with top-tier equipment like Soudronic. Can our material really keep up with those lines?

Yes, our material is specifically engineered to be compatible with and excel on high-speed welding lines, including those manufactured by industry leaders like Soudronic 10. Thanks to our strict chemical composition control and precise surface treatment, our ETP can support welding speeds up to $150 \text{ m/min}$, meeting the high-volume needs of global can makers.

The Huajiang Edge on High-Speed Lines

A high-speed welding line cannot afford stops, stuttering, or inconsistent welds. The machine is only as good as the raw material it feeds on. Our quality control processes are built to support this high-demand environment.

Consistent Surface Treatment

The surface of ETP is not just tin; it has a very thin, passivated layer on top, usually a chromate or chromium-free passivation layer.

- Controlling the Passivation Layer: This layer is essential for preventing premature oxidation of the tin and ensuring good lacquer adhesion. However, if this layer is too thick, it can act as a slight insulator, destabilizing the high-frequency welding current. We meticulously control the thickness of this passivation layer to meet food safety standards and maintain the necessary electrical conductivity for fast welding.

The Full-Chain Advantage

As a full-chain manufacturer, we control every step, from the moment the steel coil arrives to the final cut sheet or lid. This means we can guarantee the performance profile needed for high-speed welding.

| Weld Performance Factor | Huajiang Control Point | Impact on High-Speed Welding |

|---|---|---|

| Weld Fire/Arcing | $\pm 1\mu\text{m}$ Tin Thickness Control | Stabilizes current flow, reducing welding defects. |

| Weld Brittleness | Base Steel LCAK/DR-8 Grade | Ensures weld ductility for subsequent seaming/flanging. |

| Electrode Wear | Precise Passivation Layer | Ensures smooth current transfer, extending electrode life. |

| Throughput | 100,000 Tonne Inventory | Guarantees continuous supply to avoid line stoppage. |

For Carlos Gomez, who demands high-volume, consistent supply, the supply chain stability is as important as the material quality. Our 100,000-tonne coil inventory and immense capacity (over 6 billion lids per year) mean that when their production ramps up during the harvest season, the material will be there, cut to the exact size, and ready for their high-speed lines. This is the ultimate risk reduction—the core requirement for a procurement director.

Conclusion

Our ETP is built for your high-speed welding lines through precise control over base steel, tin coating, and surface treatment, ensuring strong, consistent, and food-safe can seams every single time.

Footnotes

1. Understand the importance of consistent material properties for high-speed can production. ↩︎

2. Learn more about the production and properties of low carbon cold-rolled steel used in can making. ↩︎

3. Technical guide on how Phosphorus impurities affect the mechanical strength and weldability of steel. ↩︎

4. Detailed information on tin coating application methods and standards for tinplate products. ↩︎

5. Overview of the three-piece can manufacturing process, including side-seam welding. ↩︎

6. Explore the specialized inks and printing processes used for food-safe tinplate packaging. ↩︎

7. Technical explanation of the side-stripe application process for internal weld seam protection. ↩︎

8. In-depth technical guide to the principles and application of electric resistance welding (ERW). ↩︎

9. Official standard methods for testing the ultimate tensile strength of metallic materials like steel. ↩︎

10. Information on high-speed welding equipment and technology from a leading industry manufacturer. ↩︎