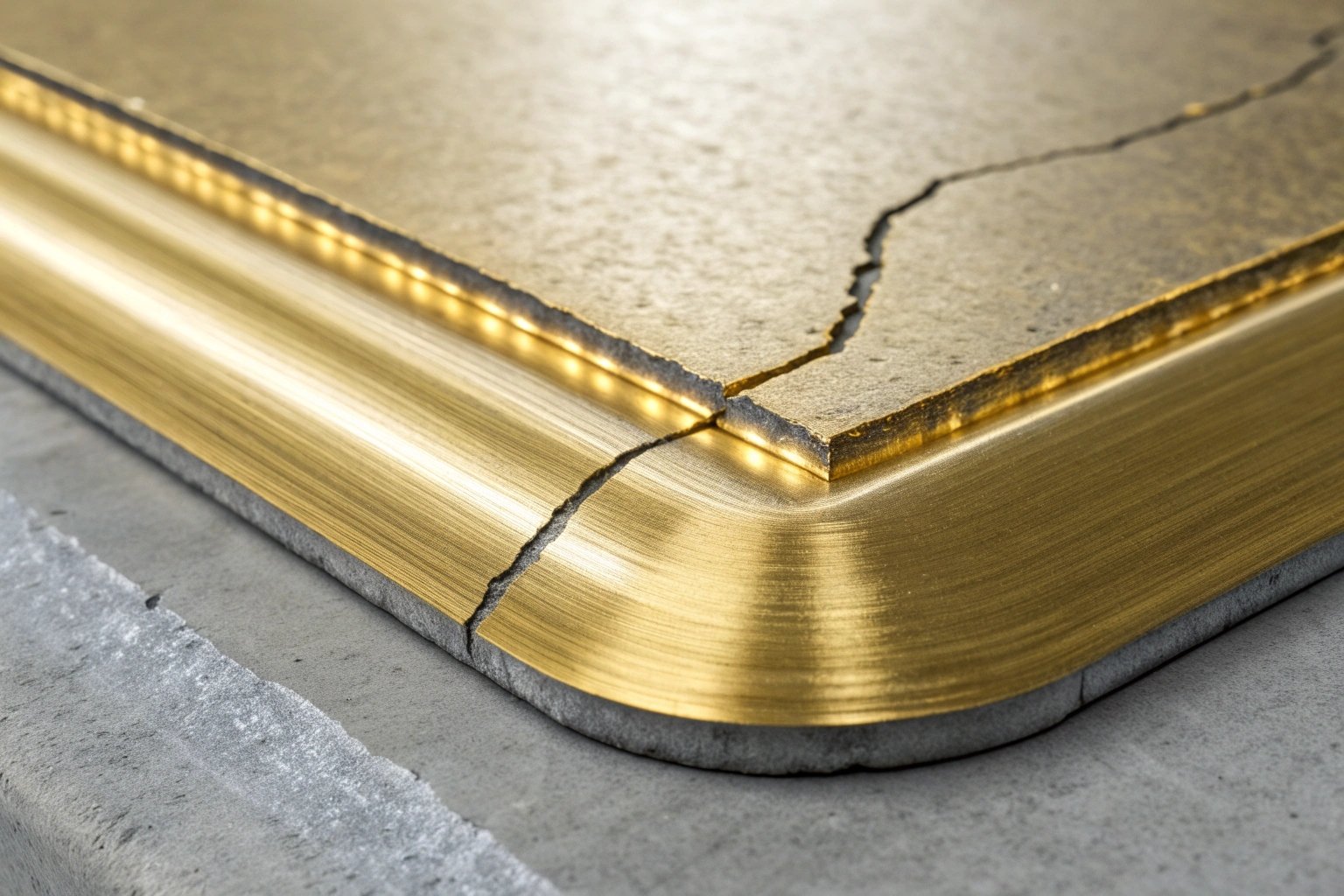

I have spent years watching how a tiny scratch on a metal lid can ruin an entire shipment of food, and it usually starts at the most vulnerable spot: the curl. If you don’t protect that edge, moisture and oxygen will find the steel, causing rust that spreads faster than you might think.

The repair coating on the curl is critical because the mechanical process of bending the tinplate often creates microscopic cracks in the original lacquer. Without a secondary repair layer to seal these gaps, the exposed metal reacts with the air and food contents, leading to rapid corrosion, rust, and potential leakage.

You might think a small scratch is no big deal, but in the world of professional food packaging, it is the difference between a happy customer and a massive financial loss. Let me explain why this extra step in our factory at Huajiang is something we never skip.

Why is the repair coating on the curl critical for preventing rust?

I often see buyers focus only on the flat part of the lid, but I always tell them to look closely at the curved edge where the metal is bent. When we shape the tinplate to form a curl, the metal stretches and the original protective paint can snap or thin out, leaving the raw steel wide open to attack.

A repair coating acts as a vital safety net that fills in these micro-fractures, creating a continuous waterproof barrier that keeps the steel from ever touching the environment. This ensures that even under the high heat of a cooking retort, the metal stays protected and the food stays safe from rust contamination.

The Science of the "Stress Point"

When we manufacture tinplate bottom ends at Huajiang, we use high-speed machines. The curl is the area that faces the most "stress." Imagine a piece of plastic—if you bend it too far, it turns white and cracks. Metal does the same thing on a microscopic level. Even the best quality tinplate from suppliers 1 like Baosteel or Shougang can show tiny "pinholes" after the curling process.

If we don’t apply a repair coating, the moisture in the air or the liquid inside the can starts a chemical reaction with the iron in the steel. This is why we use high-adhesion resins 2 like epoxy-phenolic or polyurethane. These materials "wet" the surface, meaning they flow into every tiny crack before they harden. We strictly control the dry film thickness 3 between 8-12μm. If it is too thick, your seaming machine won’t fit right; if it is too thin, it won’t stop the rust.

Why Surface Tension and Adhesion Matter

The repair paint must be special. It cannot just sit on top; it must "grip" the original layer. We ensure our coatings have high flexibility. This is important because after we ship these ends to you, your machines will bend them again during the "seaming" 4 process onto the can body. If the coating is too brittle, it will flake off right when you need it most. Our 27 years of experience has taught us that a 4B grade adhesion rating is the minimum requirement for a safe product.

Material Compatibility Table

| Feature | Standard Interior Lacquer | Repair Coating (Curl) |

|---|---|---|

| Primary Goal | General surface protection | Sealing cracks and "healing" damage |

| Flexibility | Medium | Very High (must survive seaming) |

| Application | Sheet coating (before forming) | Local spray or dip (after forming) |

| Drying Method | High-temp oven (200°C+) | Quick-dry (80-100°C) |

How can I test the integrity of the repair coating at my factory?

I know that as a procurement manager, you need more than just my word; you need proof that the lids you buy from us will hold up in your warehouse. I always suggest my clients run a few simple tests to see if the coating is actually doing its job or if it’s just for show.

The most effective way to test repair coating integrity is through a copper sulfate immersion test or an enamel rater test, which uses electricity to find "leaks" in the paint. If the coating is solid, no current will pass through and no copper will deposit on the metal, proving it is fully sealed.

The Enamel Rater Test (The Industry Gold Standard)

This is how we verify quality at Huajiang. We place the lid in a conductive liquid and pass a small electric current through it. If there is a hole in the coating as small as a needle point, the machine will show a reading in milliamperes (mA).

- Low Reading (0-5 mA): Excellent. The coating is a perfect shield.

- High Reading (>25 mA): Danger. There are holes where rust can start.

The Retort Stress Test

Since most of our clients, like Carlos, work with canned vegetables or meats, the lids must survive a "retort." This is essentially a giant pressure cooker 5. We put our coated ends into 121°C steam for 60 to 90 minutes. After they come out, we look for "blushing" (where the paint turns white) or peeling. If the repair coating stays clear and stuck to the metal, it passed. We also perform 48-hour salt spray tests 6 to simulate long-term storage in humid seaside warehouses.

Quality Verification Checklist

| Test Name | What it Measures | Success Criteria |

|---|---|---|

| Copper Sulfate Test | Physical holes in coating | No dark spots or copper plating visible |

| Cross-Hatch Test | Coating adhesion strength | No paint flakes off (Grade 4B or higher) |

| Salt Spray (48h) | Long-term rust resistance | Zero rust spots on the curl area |

The "Squeeze" Test

Sometimes the simplest tests are the best. I often take a finished end and squeeze the curl with a pair of pliers to simulate a rough seaming process. Then I check with a magnifying glass to see if the repair coating cracked. If the coating is high-quality, it should stretch with the metal, not snap like glass. This flexibility is what allows our products to meet FDA and EU food safety standards 7 consistently.

Does the repair coating color need to match the internal lacquer?

I often get asked if the color really matters. Some people want a perfect match, while others don’t care as long as it works. In my experience, while color is mostly about looks, it can also tell you a lot about what is inside the coating and how it will perform with your food product.

The repair coating color does not strictly need to match the internal lacquer for safety, but using a matching color provides a professional look for the consumer. More importantly, the chemistry must match; for example, a gold epoxy repair coating should be used over a gold epoxy base to ensure they bond together correctly.

Aesthetics vs. Function

In the B2B world, branding is huge. If you are selling premium canned tuna, a bright silver scratch on a gold lid looks like a defect to the shopper. That is why we offer 4-6 color custom printing and color-matched repair lacquers. However, I always remind my customers that the chemical "friendship" between the two layers is the real priority. If you put a water-based repair over an oil-based lacquer, it might peel off regardless of the color.

Understanding Coating Types

| Coating Type | Common Color | Best For |

|---|---|---|

| Epoxy Phenolic | Gold / Amber | High-acid foods (Fruits, Tomatoes) |

| Organosol | Clear / White | Severe forming (Deep draws) |

| Polyester (BPA-NI) | Clear | Modern safety standards (EU/US markets) |

Why "Clear" is Popular

Many of our global clients are moving toward clear repair coatings. Why? Because it allows the quality control team to see the metal underneath. If rust starts to form under a clear coat, you will see it immediately. With a thick gold or white "mask," you might not know there is a problem until the can starts to leak on a supermarket shelf. At Huajiang, we help you choose based on your specific food type 8—whether it is high-sulfur meat or low-acid vegetables.

The Role of Pigments

Sometimes, the color is actually a functional ingredient. White coatings 9 often use titanium dioxide, which helps the lid resist "sulfide staining" (that ugly black look you see in meat cans). If your base lacquer is white for this reason, your repair coating should probably be white too, to maintain that chemical protection. Our technical team can help you diagnose exactly which coating matches your specific sterilization process.

What happens if the curl coating fails during the retort process?

I have seen the aftermath of a coating failure, and it isn’t pretty. It usually starts with one "blown" can in a warehouse and ends with a million-dollar recall. If that repair coating on the curl fails when it hits the high heat of the retort, the protective barrier is gone before the can even leaves your factory.

If the curl coating fails during the retort process, the metal is exposed to high-temperature steam and acidic food juices, causing "retort staining" or "blackening." This not only makes the product look unappealing but also weakens the metal, which can lead to "fatigue" and eventual leaking of the vacuum seal.

The "Black Spot" Problem

During cooking, certain foods like corn or fish release sulfur. If the coating on the curl has cracked and hasn’t been repaired, the sulfur reacts with the iron to create iron sulfide. This looks like black, soot-like spots. It isn’t necessarily poisonous, but no consumer is going to eat food out of a can that looks like it has mold or dirt inside it. This is why we emphasize high-temperature resistance 10 at 121°C for all our repair systems.

The Risk of "Fatigue"

A failed coating doesn’t just look bad; it’s a structural risk. Rust eats away at the thickness of the tinplate. Since the curl is part of the "double seam" that keeps the can airtight, any loss of metal thickness means the seal is no longer tight. I have seen cases where the vacuum was lost because rust created "micro-paths" for air to get in. Once air gets in, bacteria follow, and the food rots. This ruins the hard work of your entire production line.

Huajiang’s Prevention Strategy

We avoid these disasters by maintaining a massive stock—over 100,000 tons—of premium raw materials. This allows us to select the exact right thickness and temper of steel that won’t crack too much during forming. We also use 53 Japanese Fuji coating lines, which are the most precise in the world. We make sure the repair coating is cured at exactly the right temperature so it becomes a "part" of the lid, not just a layer on top. This is how we keep our costs 5-8% lower than others—by doing it right the first time and avoiding the cost of waste.

Conclusion

Protecting the curl with a high-quality repair coating is the only way to guarantee long-term food safety and brand reputation. At Huajiang, we ensure every lid we ship is a perfect shield for your products.

Footnotes

1. Explore global tinplate production standards from leading steel manufacturers like Baosteel. ↩︎

2. Technical insights into chemical resin technologies for industrial protective coatings. ↩︎

3. Understanding the precision measurement of dry film thickness in metal packaging. ↩︎

4. Industry news and technical guides on the canmaking and seaming process. ↩︎

5. Overview of industrial retort systems and sterilization equipment for the food industry. ↩︎

6. Official ASTM B117 standard practice for operating salt spray (fog) apparatus. ↩︎

7. FDA regulatory information regarding food contact substances and safety compliance. ↩︎

8. International food standards and guidelines for canned goods from the FAO. ↩︎

9. Leading innovations in high-performance metal packaging and internal coatings. ↩︎

10. Technical resources on thermal processing and high-temperature material stability. ↩︎