I hate seeing good metal go to the scrap bin because it feels like I am throwing my client’s money directly into the trash can.

Scroll shearing is almost always the better choice for cost efficiency when producing round bottom ends. It uses a wave-like cutting pattern to nest circles closer together, which saves 3% to 8% of the material compared to straight cutting.

Now, let’s look at the math, the quality implications, and exactly when you should switch methods to protect your margins.

How much material cost can I save with scroll shearing?

I once sat down with a client from Spain and calculated his waste on straight shearing, and the final dollar amount for the year shocked us both.

You can typically save between 3% and 8% on your total tinplate material costs. This happens because the zigzag cut allows the circular ends to fit into the empty spaces of the next row.

To understand the real value here, we need to dive deep into the geometry of the metal sheet. This is not just about cutting lines; it is about maximizing the surface area of the expensive Electrolytic Tinplate (ETP) 1 that you are paying for.

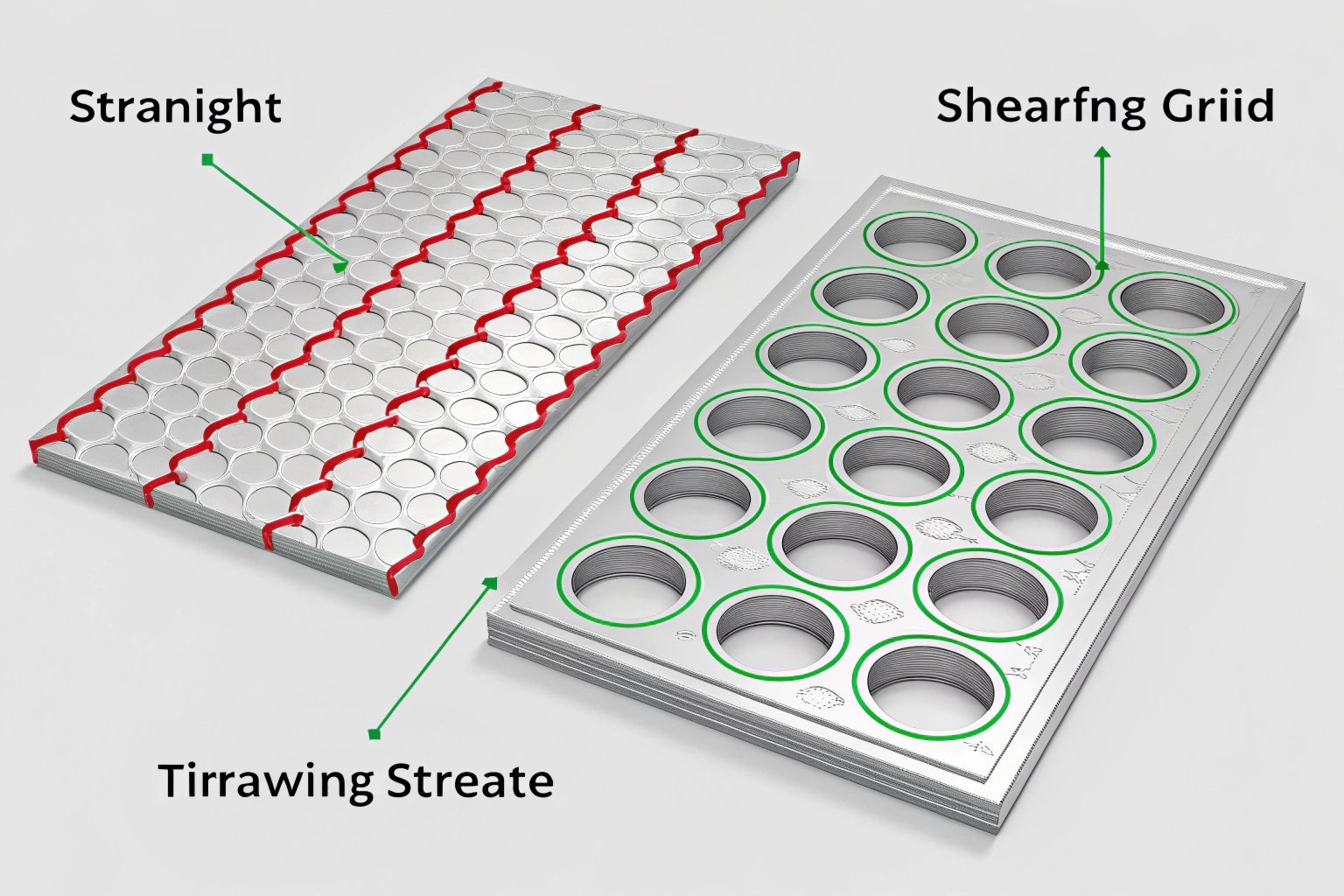

When you use straight shearing (also known as straight cutting), you are processing the master coil into simple rectangular sheets. Imagine a grid of perfect squares. Now, try to fit circles (your can bottoms or lids) into those squares. You will immediately see triangles of empty space between every single circle. That space is waste. In the industry, we call this the "web" or the "skeleton." With straight shearing, the web is thick and represents a significant percentage of the sheet area that cannot be used. You paid for that steel, but you cannot turn it into a product.

Scroll shearing changes this geometry entirely. Instead of a straight line, the blade cuts a specific wave pattern. This is often called the "primary scroll." This wave shape allows the circles in the second row of the sheet to sit inside the gaps of the first row. It is exactly like a zipper closing. The "teeth" of one row fit into the gaps of the other.

By doing this, we reduce the "web" between the ends to a bare minimum. For high-volume production, such as standard 307 (83mm) or 401 (99mm) bottom ends, this reduction in waste is massive.

Here is a breakdown of the financial and physical differences:

Cost Efficiency Comparison Table

| Feature | Straight Shearing | Scroll Shearing | Impact on Your Wallet |

|---|---|---|---|

| Shape of Sheet | Rectangular | Wave-edged (Scrolled) | Scroll uses more surface area effectively. |

| Material Yield | 78% – 82% | 85% – 91% | You get more lids from the same weight of coil. |

| Scrap Rate | High (18% – 22%) | Low (9% – 15%) | You sell less scrap, but you buy less steel. |

| Price Per Sheet | Lower processing cost | Higher processing cost | The material saving usually outweighs the processing fee. |

At Huajiang, we manage a massive inventory of 100,000 tons of coil. I often analyze orders for my clients. If a client orders 500 tons of tinplate for making bottom ends, a 5% saving equals 25 tons of steel. At current market prices, that is a huge amount of money.

The calculation is simple. If you stick with straight shearing for round parts, you are paying for corners on the sheet that do not exist on your final product. Scroll shearing eliminates those corners before they even enter your press. While the processing fee for scroll shearing is slightly higher because the machinery is more complex, the reduction in raw material consumption makes it the clear winner for any order volume over 20 tons.

Does scroll shearing affect the physical quality of the bottom ends?

Saving money means absolutely nothing if your production line jams or if the ends fail the salt spray test 2 later due to poor edge quality.

Scroll shearing generally improves the physical quality of the bottom ends by providing a cleaner edge. Straight shearing can sometimes create tiny metal slivers or burrs that damage the coating or contaminate the can.

When we talk about quality in can making, we are often talking about the edges of the metal sheet. This is a technical detail that sales people rarely discuss, but it is vital for your factory manager and your quality control team.

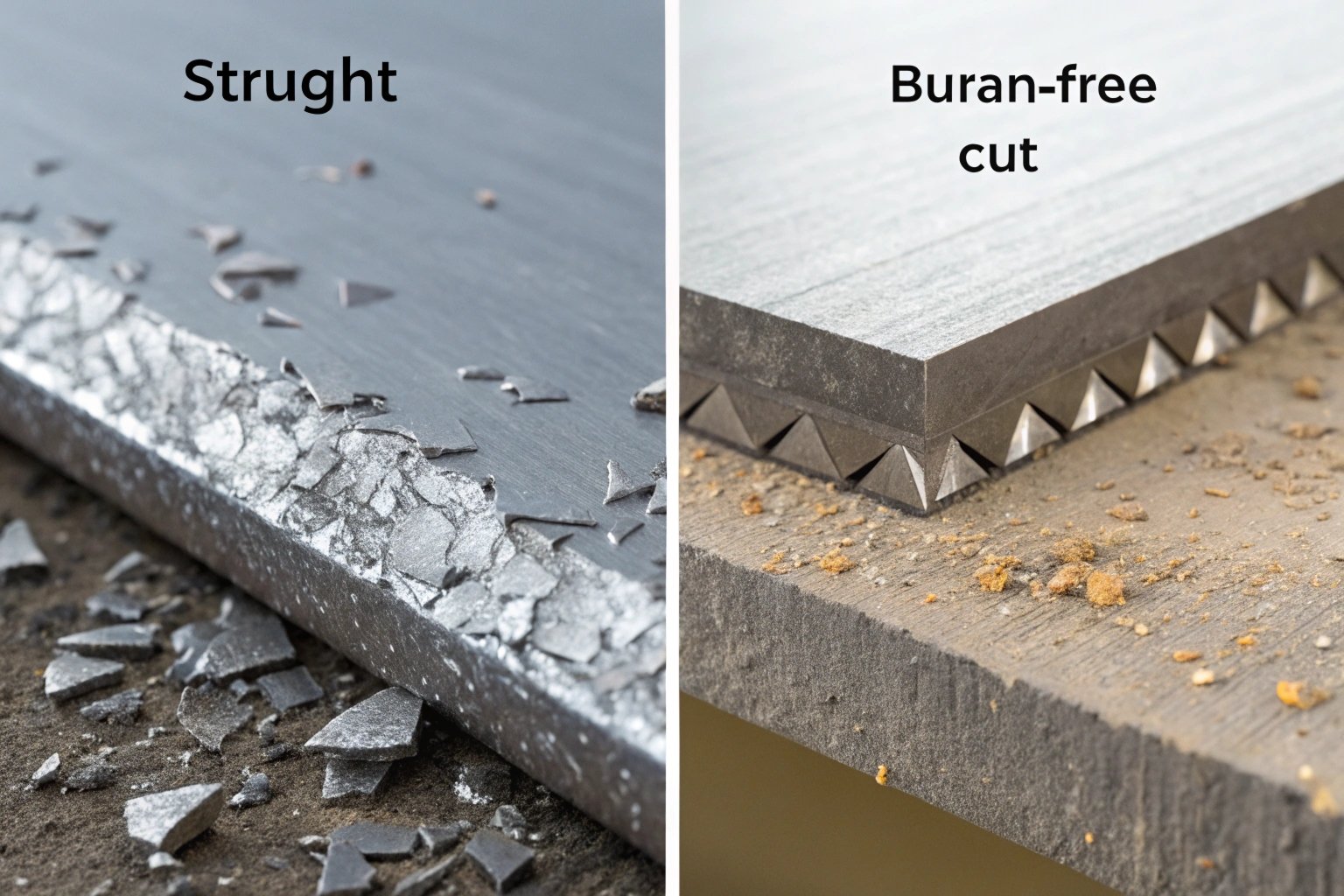

The mechanical action of the two methods is different. A straight shear usually operates like a guillotine. It chops the metal. If the blade gap is not set perfectly, or if the blades are dull, the machine might "tear" the metal slightly rather than slicing it clean. This leaves a "burr" (a rough, raised edge) or generates "angel hair."

What is Angel Hair?

"Angel hair" refers to microscopic slivers of tinplate that break off the edge of the sheet during the cutting process. These are dangerous for two main reasons:

- Contamination: If that sliver falls into the can, you have physical contamination. For a buyer dealing with strict FDA or EU food safety standards 3, this is a disaster. It can lead to product recalls.

- Tooling Damage: These slivers can build up in your press dies, causing wear and tear on your expensive tooling.

Scroll shearing lines are different. They are high-precision, automated machines designed specifically for the can-making industry. They use rotary dies 4 or high-speed punch shears that maintain very tight tolerances. This results in a cleaner cut with fewer burrs.

The Corrosion Risk

The quality of the cut edge also affects corrosion resistance 5. This is critical for the "Normal End" or bottom end of a can. You usually apply a lacquer (coating) to protect the metal. If the edge of the sheet is rough or has a large burr, the lacquer might pull away from that sharp point during curing. This creates a microscopic weak spot where raw steel is exposed.

If you are packing acidic foods—like tomato paste, pineapple, or pickles—the acid will attack that exposed spot. This leads to rust, and eventually, the can might swell or leak. This is why for high-acid foods, we almost exclusively recommend scroll shearing to ensure the best possible edge integrity.

Comparison of Edge Defects

| Defect Type | Straight Shearing Risk | Scroll Shearing Risk | Consequence |

|---|---|---|---|

| Burrs | Moderate to High | Low | Lacquer failure, rust on the edge. |

| Angel Hair | High | Low | Contamination inside the can. |

| Squareness | Variable | Very High Accuracy | Jamming in the feeding magazines. |

Additionally, scroll sheets are designed to feed directly into high-speed shell presses 6. The "step" accuracy (the distance between cuts) is monitored by computers. This ensures that when your press punches the end, the lithography (the printed design) is perfectly centered. Straight cut sheets often rely on mechanical gauges in the press, which can slip at high speeds, leading to off-center designs.

Why is scroll shearing considered more eco-friendly for production?

Sustainability is not just a marketing buzzword anymore; it is a hard requirement for many of my European buyers who need to report carbon usage.

Scroll shearing is more eco-friendly because it significantly reduces the carbon footprint per unit produced. By generating less scrap metal, you reduce the energy consumed in mining, smelting, and transporting steel.

We need to think about the lifecycle of the steel to understand the environmental impact. Every kilogram of tinplate requires a significant amount of energy to produce. The process starts with mining iron ore, transporting it, smelting it in a massive blast furnace, refining it into steel, rolling it into coils, and finally electro-plating it with tin. This entire chain releases CO2.

When you use straight shearing and generate 20% scrap waste, you are effectively saying that 20% of that energy was wasted on metal that will just be melted down again. Yes, steel is 100% recyclable, which is great. But recycling itself takes energy. You have to collect the scrap, bail it, transport it back to the steel mill, and melt it in an electric arc furnace 7.

The Energy Equation

By using scroll shearing, you improve your material yield significantly. You might get 1,000 can ends from 10kg of steel instead of 11kg. This efficiency ripples through the entire supply chain:

- Less Raw Material Extraction: You are ordering fewer coils for the same production output. This means less iron ore is mined.

- Less Global Logistics: Most tinplate moves across oceans. If you are in Mexico buying from China, you are paying to ship the steel. If 8% of that steel is scrap, you are burning bunker fuel to ship waste across the Pacific Ocean. Scroll shearing keeps that waste in the steel mill (or minimizes it), so you only ship usable product.

- Less Waste Handling: Inside your factory, handling scrap takes energy. You need forklifts, baling machines, and space. Reducing scrap reduces your internal energy usage.

This is a very strong point for your annual sustainability report. Large food groups (like Nestle or Kraft Heinz) often have targets to reduce their "Scope 3" 8 emissions. Scope 3 includes the emissions from their supply chain. By purchasing scroll-cut sheets, or ordering ends made from scroll-cut sheets, you can prove that you are using the most efficient manufacturing method available.

Furthermore, modern scroll shearing lines, like the ones we operate at Huajiang, are often equipped with better stacking and packaging systems compared to older straight shears. This reduces damage during transit. Damaged sheets are another form of waste. If the corner of a straight-cut bundle gets bent, you might lose 50 sheets. Scroll bundles are often packed more securely due to their interlocking shape, further reducing the carbon footprint 9 of lost product.

Can I demand scroll shearing to lower my overall purchase price?

You want the best price, but you need to know which lever to pull during our negotiation to get the deal you actually want.

You can certainly demand scroll shearing to lower costs, but this usually requires meeting a Minimum Order Quantity (MOQ). The setup cost for scroll dies is higher, so it only makes financial sense for large, consistent orders.

This is where the business reality meets the engineering theory. As a manufacturer, I want to save you money because it makes you competitive, which means you buy more from me. However, I also have operational costs that we must consider.

The setup process for the two machines is very different.

- Straight Shear: This is fast and flexible. We just set the length and width coordinates on the computer, and the blade starts cutting. We can do this for a very small order, perhaps just 5 tons.

- Scroll Shear: This requires specific tooling. We have to install specific scroll dies that match the exact diameter of your can end (e.g., 307, 401, or 603). Changing these dies takes time and skilled labor.

If you come to me and say, "Chase, I need 500 sheets for a test run," I will likely recommend straight shearing. The cost to stop the line and set up the scroll dies would be higher than the value of the metal you save on such a small batch. However, if you say, "I need regular shipments for the upcoming tomato harvest season," then scroll shearing is the only logical choice.

When to Switch to Scroll Shearing

Here is a simple guide to help you decide when to push for this in your contract:

| Your Situation | Recommended Method | Why? |

|---|---|---|

| Trial Order / Small Batch | Straight Shearing | Low setup cost, quick delivery. |

| High Value Printed Sheets | Scroll Shearing | The print adds value; waste is more expensive. |

| Standard Sizes (307/401) | Scroll Shearing | We likely have the dies ready; easy savings. |

| Irregular/Custom Sizes | Straight Shearing | Custom scroll dies are expensive (CAPEX). |

The "All-In" Cost Strategy

When you negotiate with suppliers like Huajiang, you should look at the "All-In" cost, not just the processing fee.

- Option A (Straight): Lower processing fee + Higher material cost.

- Option B (Scroll): Slightly higher processing fee + Much lower material cost.

For any serious volume, Option B always wins. The "tipping point" is usually quite low. Once you are buying more than 20 or 30 tons of a single size, scroll shearing becomes the winner.

Also, consider the supply chain resilience 10. Because we hold such a massive stock of master coils (100,000 tons) from top mills like Baosteel, we can cut scroll sheets on demand. This is better for you than buying pre-cut straight sheets from a trader who has limited stock. You get the efficiency of custom cutting with the speed of ready stock. You can lock in your price based on the coil weight, but pay for the efficiency of the scroll cut.

Conclusion

If you are running a serious canning operation, scroll shearing is the smart move. It saves you 3-8% in material costs, ensures better edge quality for your liners, and reduces your environmental impact. While straight shearing has its place for small, quick jobs, the math simply favors scroll cutting for volume production.

Footnotes

1. Specifications and uses of electrolytic tinplate in packaging. ↩︎

2. Standard practice for operating salt spray apparatus. ↩︎

3. Regulatory overview for food contact substances and packaging. ↩︎

4. Explanation of rotary die technology in manufacturing. ↩︎

5. Definition and factors influencing material corrosion resistance. ↩︎

6. Insights into high-speed machinery for can manufacturing. ↩︎

7. How electric arc furnaces recycle scrap steel. ↩︎

8. Protocol for calculating indirect supply chain emissions. ↩︎

9. Tools to calculate and understand carbon footprint impact. ↩︎

10. Strategies for building resilient global supply chains. ↩︎