I have seen too many buyers lose significant amounts of money by choosing cheap materials without fully understanding the risks involved. You need to know exactly what you are paying for before signing that contract to protect your production line.

Prime Electrolytic Tin Plate meets strict standards for thickness, coating, and safety, making it perfect for food canning. Secondary plate contains defects like scratches, uneven coating, or dimension errors, making it unsafe for food but suitable for industrial use.

Understanding the gap between these two grades is not just about price; it is about knowing where your product will end up. If you use the wrong material for the wrong application, you risk product failure, machine damage, and heavy financial claims. Let us break down the technical differences so you can make the right choice for your business.

Is secondary tinplate safe for food contact applications?

Imagine opening a can of food and finding rust inside or realizing the seal has failed. That is the nightmare scenario I want to help you avoid when choosing your materials.

No, secondary tinplate is generally not safe for direct food contact. It often lacks the necessary tracking and safety certifications found in prime material, increasing the risk of contamination or chemical leakage.

When we talk about food safety, there is zero room for error. This is not just about following rules; it is about protecting the health of the final consumer. In my twenty years in the manufacturing industry, I have seen that the biggest difference between prime and secondary material lies in the "invisible" qualities that define safety.

The Risk of Surface Defects and Chemical Reaction

Secondary tinplate often comes from batches that failed quality control. These failures might be visible, like scratches, but often they are microscopic. Pinholes are a major concern. A pinhole is a tiny break in the steel sheet that is invisible to the naked eye. If you use this for a tomato sauce can or a fruit cup, the acid in the food will react with the exposed steel base. This chemical reaction causes hydrogen swell 1 to form, making the can swell. This spoils the food and can potentially harm the person who eats it. Prime material goes through rigorous online pinhole detection to ensure zero pinholes, whereas secondary material does not offer this guarantee.

Lack of Traceability and Certification

Another critical issue is the paper trail. Prime material comes with a Mill Test Certificate 2 (MTC). This document is the DNA of the steel. It proves the chemical composition and confirms it is free from harmful heavy metals like lead or cadmium. Secondary material is often sold "as-is" without these papers. You cannot prove where the scrap metal came from. In many cases, secondary plate is made from recycled scrap that was melted down. Without proper certification, you cannot pass FDA (USA) 3 or LFGB (Europe) 4 inspections. If you are exporting to Europe or North America, using uncertified material is a business risk you cannot afford to take. A single recall could bankrupt a small canning factory.

Comparative Safety Standards

To help you visualize the safety gap, here is a breakdown of the safety features:

| Feature | Prime Grade (Food Safe) | Secondary Grade (Non-Food) |

|---|---|---|

| Raw Material Source | 100% New Cold Rolled Substrate | Often Recycled/Remelted Scrap |

| Pinholes | Strictly Zero Allowed | Possible/Common |

| Heavy Metal Content | Tested & Certified Low | Unknown/Untested |

| Certification | FDA, RoHS, ISO9001 Available | Usually None |

In summary, while it might be tempting to use cheaper steel for a food can, the risk of a recall or a lawsuit far outweighs the savings. Secondary plate has its place, but that place is never in contact with food.

How much money can I save by buying secondary grade?

We all want to cut costs, but does a lower price tag today mean more profit tomorrow? I have learned that the cheapest option is often the most expensive in the long run.

You can typically save 20% to 40% on the purchase price by choosing secondary grade over prime. However, you must calculate the hidden costs of extra sorting, higher waste rates, and potential customer claims.

The allure of a 30% discount is powerful. If you are buying ten containers of tinplate, that is a massive amount of cash flow saved upfront. However, as someone who values efficiency, I need you to look at the Total Cost of Ownership 5 rather than just the invoice price. The sticker price is only the beginning of the story.

The Hidden Cost of Processing and Labor

When you buy Prime material, you put the coil on your machine, hit "start," and walk away. The machine runs smoothly because the steel is consistent. With secondary material, the thickness might vary. One section of the coil might be too thick, which can jam your stamping press. Every time your machine stops, you are losing money. You have to pay your workers to fix the jam, and you lose valuable production time. I have seen factories where the line stopped every hour because of bad steel. At the end of the day, their "cheap" steel cost them more in lost labor and downtime than if they had bought the good stuff. You also need to pay staff to manually sort the good sheets from the bad sheets, which adds a significant labor cost.

Yield Loss and Scrap Rates

Another factor is yield. Yield is the percentage of the material you actually turn into a product. With Prime plate, you might use 98% of the coil. With Secondary plate, you might find a large rusted patch in the middle of the roll. You have to cut that section out and throw it away. If you end up scrapping 15% of the material because of defects, your 20% price savings effectively disappears. You are paying for weight that you simply throw in the trash bin. You are also paying freight and import duties on that trash.

Smart Market Positioning

However, there is a smart way to use these savings. If you are manufacturing products that do not require high precision—like industrial waste bins, simple metal trays, or decorative signs—secondary plate is a gold mine. In these markets, the price is the only thing that matters. Your competitors are likely using secondary material, so if you stick to prime, you will price yourself out of the market. The key is to match the material to the customer’s budget and quality expectations.

Cost vs. Risk Analysis

| Cost Factor | Prime Grade | Secondary Grade |

|---|---|---|

| Initial Purchase Price | 100% (Market Rate) | 60% – 80% of Market Rate |

| Machine Downtime | Low | High (Due to jams/breaks) |

| Material Waste | < 2% | 10% – 20% |

| Ideal Market | High-end Food/Beverage | Low-end Industrial/General |

Buying secondary grade is a valid business strategy, but only if your production team is skilled enough to handle the inconsistencies and your final product allows for lower quality inputs.

What kind of defects are common in your secondary stock?

I know it is frustrating when a supplier is vague about quality. You deserve to know exactly what flaws you might find in your shipment so you can plan accordingly.

Secondary stock often includes visual defects like scratches, rust spots, and pinholes. You might also face mechanical issues such as inconsistent thickness or uneven tin coating that can disrupt your production line.

When we classify material as "Secondary," it is usually because it failed a specific test during the prime production run. Understanding these specific failures helps you decide if you can work around them. Defects usually fall into two categories: Visual and Mechanical.

Visual and Surface Defects

These are the most common issues and the easiest to spot.

- Color Stains: You might unroll a coil and see a "color stain" or yellowish tint. This happens when the passivation process 6 wasn’t perfect. For a paint can that will be covered in a paper label, this doesn’t matter at all. The steel is still strong. However, for a cookie tin where the silver metal is part of the design, this is unacceptable.

- Rust Spots: Since secondary material often sits in warehouses longer or has less protective oil, small spots of rust can appear. If you have a cleaning line, you might be able to wash this off. If not, it becomes a permanent blemish on your product.

- Scratches: Handling marks or scratches from the rollers can occur. If the scratch is deep, it ruins the tin coating and exposes the steel to rust.

Mechanical and Dimensional Inconsistencies

These defects are more dangerous because you cannot always see them with your eyes until they break your machine.

- Thickness Variation: Prime plate has a tolerance of roughly ±0.01mm. Secondary plate can vary by ±0.03mm or more. If you are making a deep-drawn part (like a two-piece can), this variation will cause the metal to crack or wrinkle in the die. This is often called earring 7 during the drawing process.

- Temper Issues: The hardness of the steel might not be uniform. One end of the coil might be soft (easy to bend), while the other end is hard (springs back). This makes it very difficult to automate your welding or folding process because the material behaves differently every few meters.

- Coating Weight: The tin layer protects the steel. In secondary lots, the tin might be very thin in some areas (differential coating errors). This reduces the shelf life of the final product because it will rust faster.

Common Defects Checklist

If you buy secondary, you should have a quality control team ready to look for these:

- Pinholes: Tiny holes visible against light.

- Blisters: Small bubbles in the coating.

- Camber: The edge of the coil is curved, not straight.

- Bad Shape: Wavy edges or buckles in the center.

If you have a manual production line where workers can visually check each piece and discard the bad ones, secondary material is manageable. But if you run high-speed automated lines, these defects will cause constant headaches and stoppages.

Do you separate prime and secondary coils clearly in the warehouse?

Mixing up material grades is a recipe for disaster. I believe strictly organizing inventory is the only way to guarantee you get exactly what you ordered.

Yes, reputable manufacturers strictly separate prime and secondary coils to prevent mix-ups. Prime coils come with full mill warranties and test certificates, while secondary coils are usually sold "as-is" without these guarantees.

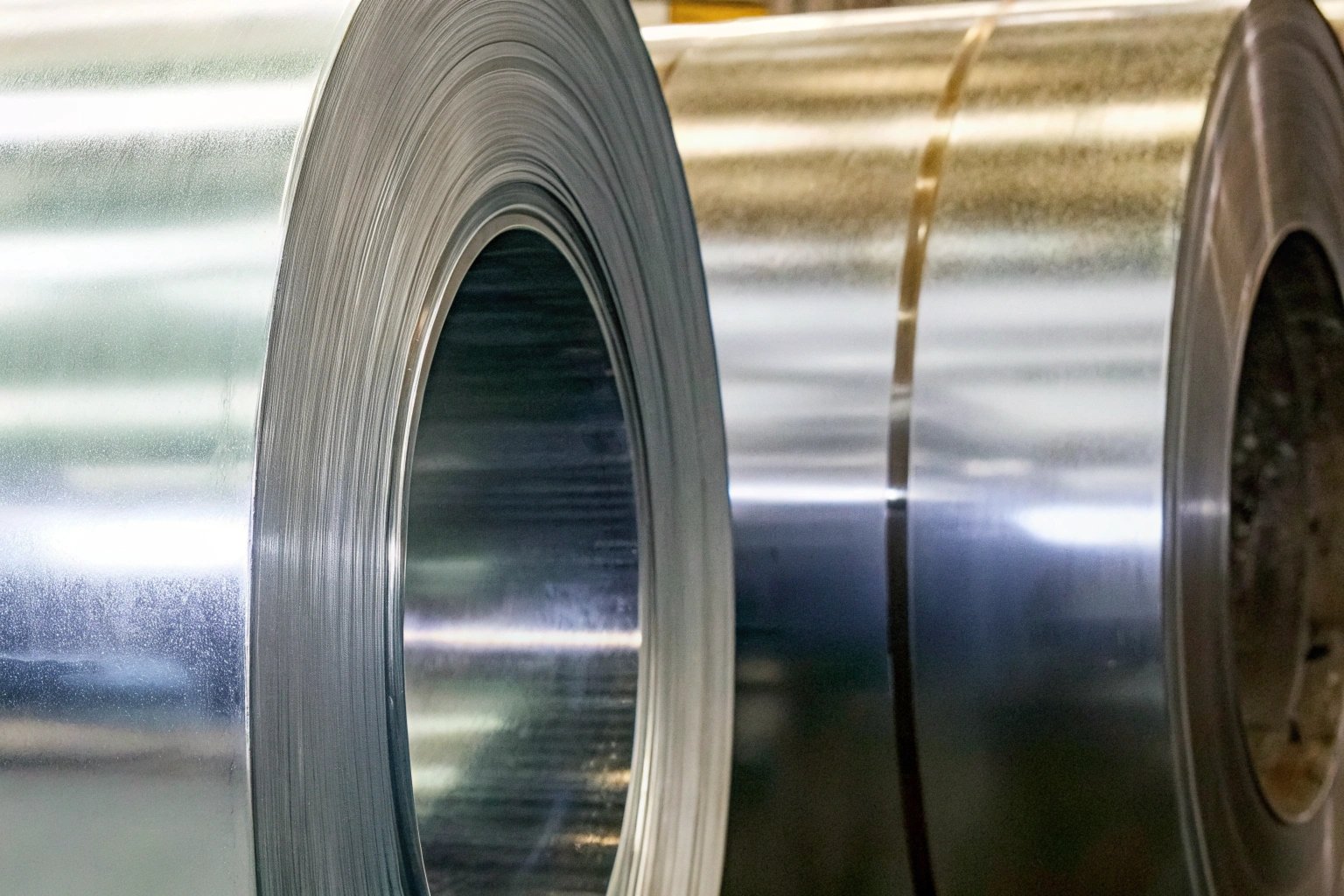

In any professional manufacturing environment, organization is the foundation of quality. The physical separation of Prime and Secondary stock is critical because they look almost identical to the naked eye. A shiny coil of steel looks like a shiny coil of steel, regardless of the microscopic defects inside.

The Importance of Physical Separation

We store Prime and Secondary materials in completely different zones. Why? Because a forklift driver in a hurry might grab the wrong coil if they are stacked next to each other. Prime coils are usually wrapped in premium packaging—often with Volatile Corrosion Inhibitor 8 (VCI) paper, metal corner guards, and hard plastic outer shells to prevent any moisture damage during sea transit. Secondary coils might have simpler packaging or recycled packaging. This visual difference acts as a first line of defense against shipping errors.

The Paperwork Difference (MTC vs. No Warranty)

The biggest separation isn’t just physical; it is legal and administrative.

When you buy Prime, you receive a Mill Test Certificate (MTC). This is the "birth certificate" of the steel. It tells you the heat number, the exact chemical yield, the tin coating weight, and the temper grade. It guarantees that the material follows ASTM A623 9 or GB/T 2520 standards. If the steel fails during production, you can use the MTC to file a claim and get your money back.

Secondary material is sold "As-Is." This is a standard trade term. It means "what you see is what you get." There is no MTC provided. There is no warranty. Once the material leaves the warehouse, it belongs to you, defects and all. Suppliers separate these in the system to ensure they never accidentally promise a warranty on a secondary product.

How to Verify Your Shipment

As a buyer, you should always check the tags on the coils when they arrive.

- Prime Tags: Will list specific grades (e.g., MR, T-4, 2.8/2.8). It will have a unique coil number that matches the documents perfectly.

- Secondary Tags: Often marked as "Second Choice," "Non-Prime," or simply "Waste Waste" (in some markets). The weight listed might be an aggregate weight rather than a precise net weight.

Inventory Management Comparison

| Aspect | Prime Inventory | Secondary Inventory |

|---|---|---|

| Storage Location | Zone A (Climate Controlled) | Zone B (Standard Storage) |

| Packaging | Premium, Heavy Duty | Standard or Minimal |

| Documentation | Full MTC Provided | Packing List Only |

| Warranty | Manufacturer Warranty | No Warranty (As-Is) |

By keeping these strictly separate, we ensure that a customer who pays for premium quality never receives a defective product, and a customer looking for a bargain gets exactly the price point they need without false promises.

Conclusion

The choice between Electrolytic Tin Plate 10 grades depends entirely on your final application. If you need safety and efficiency, stick to prime; if you need to cut costs for non-critical items, secondary is a viable option. Choose the grade that fits your business model best.

Footnotes

1. Cause of can bulging due to chemical reaction. ↩︎

2. Certified document proving metal composition and quality. ↩︎

3. U.S. agency regulating food safety and contact materials. ↩︎

4. German standard for safe food contact materials. ↩︎

5. Comprehensive assessment of all costs associated with an asset. ↩︎

6. Chemical process to prevent corrosion on metal surfaces. ↩︎

7. Defect causing wavy edges in deep-drawn metal parts. ↩︎

8. Packaging technology that releases compounds to prevent rust. ↩︎

9. Standard specification for tin mill products and requirements. ↩︎

10. Technical specifications of tin-coated steel sheets. ↩︎