I have seen many canning lines stop because of poor coating quality on bottom ends. It is a nightmare for any buyer. You need a solution that prevents rust and ensures food safety every single time.

Fuji coating lines use high-precision rollers and automated thickness controls to apply a uniform protective layer on tinplate. This prevents metal exposure, ensures acid resistance, and maintains consistent quality across millions of pieces, which is essential for global food safety standards like FDA.

Choosing the right equipment for your tinplate products is the difference between a smooth production run and a costly recall. Let me show you why top-tier machinery is the secret to your supply chain security.

How does Fuji equipment improve the consistency of the coating?

I once met a buyer who struggled with uneven coatings that led to pinhole leaks in his fruit cans. This happens when the machine cannot control the film weight properly. My team avoids this by using Fuji’s advanced technology.

Fuji coating lines improve consistency by using a closed-loop thickness control system and precision scrapers that keep the coating weight within a tolerance of ±1μm. This ensures that every part of the tinplate sheet, including edges, receives the exact amount of lacquer needed.

The Science of Uniform Layers

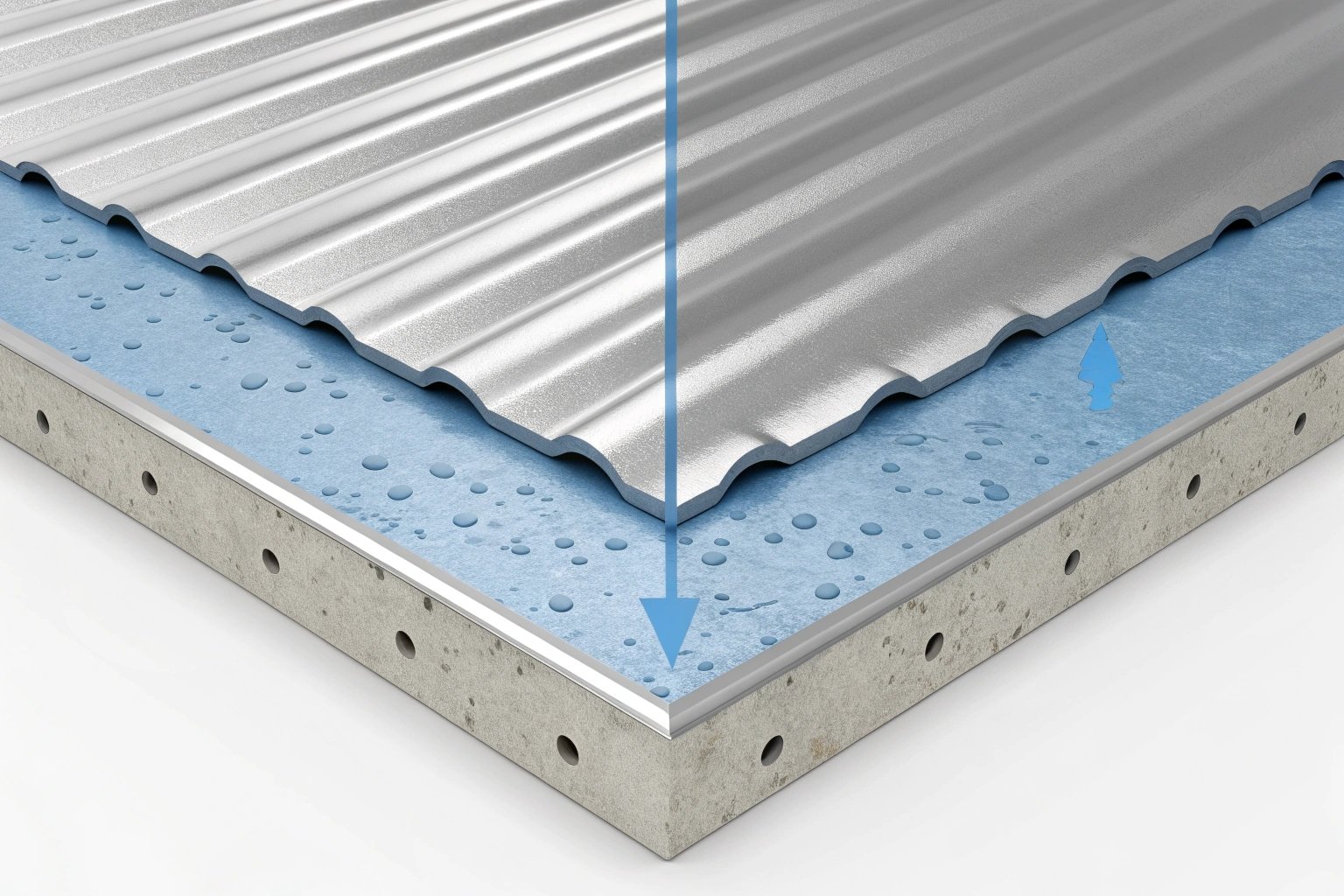

When we talk about tinplate bottom ends, the coating is the only thing protecting the metal from the food inside. If the coating is too thin, the acid in the food will eat through the metal. If it is too thick, the coating might crack during the stamping process.

At Huajiang, we use our 53 Fuji coating lines to solve this. These machines use high-precision rollers. Think of it like a professional printer but for protective lacquer. The machine monitors the thickness in real-time. If the layer shifts even slightly, the system adjusts itself immediately. This level of control is why we can handle high-acid or high-sulfur foods 1 without any risk of "fatigue" or leakage.

Precision Comparison Table

| Feature | Standard Coating Line | Fuji Coating Line | Benefit for You |

|---|---|---|---|

| Thickness Tolerance | ±3-5μm | ±1μm | Prevents rust and cracks |

| Speed | 3,000 sheets/hour | 6,000 sheets/hour | Faster delivery in peak season |

| Defect Detection | Manual Check | Automated Optical Sensors | Zero defects in your batch |

Handling Complex Geometries

Bottom ends are not flat; they have ribs and curls for strength. Standard machines often leave these areas with less coating. Fuji lines are designed to ensure the lacquer flows perfectly into every groove. This is vital for sterilization 2. When you put a can through high-heat processing, the coating must stay attached. Our Fuji lines ensure the bond between the tinplate and the lacquer is unbreakable. This is how we support large food groups that cannot afford a single "blown" can in their warehouse.

Will products from Fuji lines reduce my defect rate significantly?

I know the pain of opening a shipment and finding 5% of the lids have scratches or yellow spots. It ruins your efficiency and costs you money. I have worked hard to ensure our production eliminates these human errors.

Yes, products from Fuji lines reduce defect rates by using automated visual inspection and stabilized curing ovens. These systems detect flaws instantly and ensure the coating is perfectly hardened, preventing scratches, bubbles, or peeling during the high-speed stamping of bottom ends.

Eliminating Human Error with Automation

In a traditional factory, workers look at the sheets to find mistakes. But after eight hours, they get tired. They miss things. Fuji lines include automated visual inspection 3. These are high-speed cameras that scan every millimeter of the sheet. If there is a tiny speck of dust or a bubble, the machine marks it.

Furthermore, the environment inside a Fuji line is controlled. We keep the temperature and humidity constant. This is important because lacquer reacts to the weather. By removing these variables, we ensure that the batch you get in July is exactly the same as the batch you get in December. For a procurement director like Carlos, this consistency is the most important factor for long-term trust.

Defect Reduction Data

| Type of Defect | Impact on Production | Fuji Line Solution |

|---|---|---|

| Pinholes | Causes "blown" cans and rot | Uniform film application |

| Scratches | Leads to rust during storage | High-speed, non-contact transport |

| Incomplete Curing | Coating peels off in sterilization | Precision thermal tunnel ovens |

Better Formability

When a tinplate sheet is turned into a bottom end, it undergoes a lot of pressure. If the coating is not applied correctly, it will flake off. We call this adhesion failure 4. Because Fuji lines cure the lacquer at the perfect temperature, the coating becomes flexible. It moves with the metal. This means when your machines stamp out 500 ends per minute, the coating stays intact. This reliability is why we have a 100,000-ton stock of material ready to go—we know it will perform perfectly for our customers.

Does advanced equipment justify a slightly higher unit price?

I often hear from customers that they found a cheaper price from a small workshop. I always tell them: "Cheap today is expensive tomorrow." One bad batch of lids can cost you your entire reputation with a supermarket.

Advanced equipment like Fuji justifies its cost by lowering your total cost of ownership. It reduces waste, prevents expensive product recalls, and speeds up your production line because the materials are easier to work with. You save more on efficiency than you spend on the slight price difference.

Investing in Peace of Mind

Think about the cost of a recall 5. If you sell 100,000 cans of tuna and 1% start to leak because of bad coating, you have to pull everything off the shelves. That costs millions. When you buy from a factory like Huajiang, you are paying for the 53 Fuji lines that prevent that disaster.

Our automation also means we use less lacquer to get a better result. We pass those savings to you. In fact, our costs are often 5% to 8% lower than other large manufacturers because our Fuji lines are so efficient. We don’t waste raw materials, and we don’t waste time. For a buyer looking for a source factory 6, this is the perfect balance of quality and price.

Total Cost Analysis

- Material Savings: Precise coating means no wasted lacquer.

- Time Savings: High-speed lines mean we meet your harvest season deadlines.

- Risk Savings: FDA and SGS compliance is guaranteed, so you avoid legal fines.

By using high-end Japanese machinery, we ensure that our EOE and Normal Ends 7 meet the highest international standards. We don’t just sell metal; we sell a guarantee that your food remains safe. This is why we have grown to a 600-acre facility with over 1,800 employees. We believe in doing it right the first time.

How can I tell if a supplier is using advanced or outdated machinery?

I have seen many small traders show photos of big factories that aren’t theirs. It is hard to know who to trust when you are thousands of miles away. You need to know what to look for in a factory audit 8.

You can identify a top-tier supplier by looking for high-speed Fuji or KBA branding on the coating lines, checking for automated thickness gauges, and asking for real-time QC reports. A true manufacturer will also have a massive inventory of raw materials from major mills like Baowu or Shougang.

Signs of a Professional Operation

When you visit or video-call a factory, look at the coating section. Is it dusty? Are workers handling the sheets with bare hands? On a Fuji line at Huajiang, the process is mostly enclosed. You will see digital screens everywhere. These screens show the current temperature of the curing ovens 9 and the thickness of the coating. If a supplier cannot show you these real-time metrics, they are likely using old, manual machines.

Another sign is the scale of the warehouse. We keep nearly 100,000 tons of tinplate in stock. Only a factory with massive production capacity (like our 6 billion caps per year) can afford to hold that much inventory. This inventory management 10 is your safety net. If your demand spikes, we can start the Fuji lines immediately because we already have the steel.

Supplier Verification Table

| Indicator | Red Flag (Outdated) | Green Flag (Advanced – Huajiang) |

|---|---|---|

| Coating Machine | Local or unknown brands | Fuji (Japan) or KBA (Germany) |

| Inventory | Small, "just-in-time" stock | Huge stock (100k tons) |

| Certifications | Missing or expired SGS/FDA | Current SGS, FDA, and ISO |

| Lab Equipment | Basic scales only | Retort testers, coating weight gauges |

Technical Communication

Finally, talk to the sales team. Do they understand "sulfur resistance" or "film integrity"? If they only talk about price, they don’t understand the technical needs of your food product. My team is trained to recommend specific coatings for different foods, like tomatoes or meat. We use our Fuji lines to apply specialized resins that are designed for your specific sterilization process. This technical expertise, combined with the best machinery in the world, is what makes us a leader in the global B2B metal packaging market.

Conclusion

High-quality Fuji coating lines ensure your tinplate bottom ends are safe, consistent, and durable. This investment protects your brand and your customers from the risks of metal packaging failures.

Footnotes

1. Explanation of why specific food types require chemical-resistant lacquer. ↩︎

2. Scientific principles of heat processing to ensure food shelf-life. ↩︎

3. How AI-driven cameras detect microscopic surface defects in manufacturing. ↩︎

4. Understanding why coatings detach from metal surfaces under stress. ↩︎

5. Financial and reputational consequences of pulling products from market. ↩︎

6. Definition and importance of buying directly from the production site. ↩︎

7. Technical guide to different types of metal can lids. ↩︎

8. Standard procedures for evaluating a manufacturer’s capability and quality. ↩︎

9. The role of thermal processing in setting industrial coatings. ↩︎

10. Best practices for maintaining stock levels in global supply chains. ↩︎